Miura Tessellation Study

This exploration attempted to take a simple tessellation folded using a material of "negligible" thickness, which was then transferred to "thick" materials. Foam core was the base "thick" folding material and the MDF was a study to tease out different three-dimensional properties using the same folding pattern.

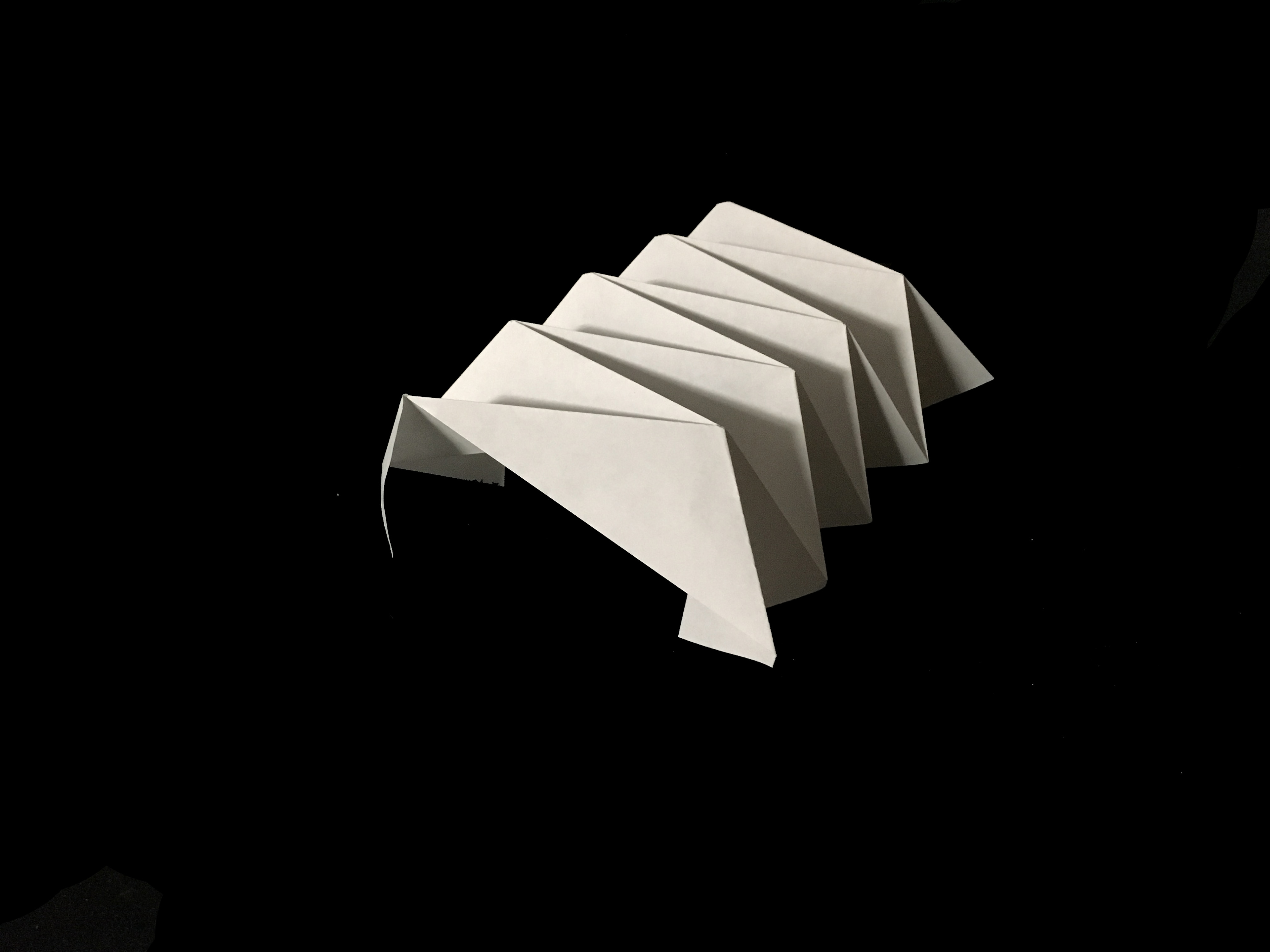

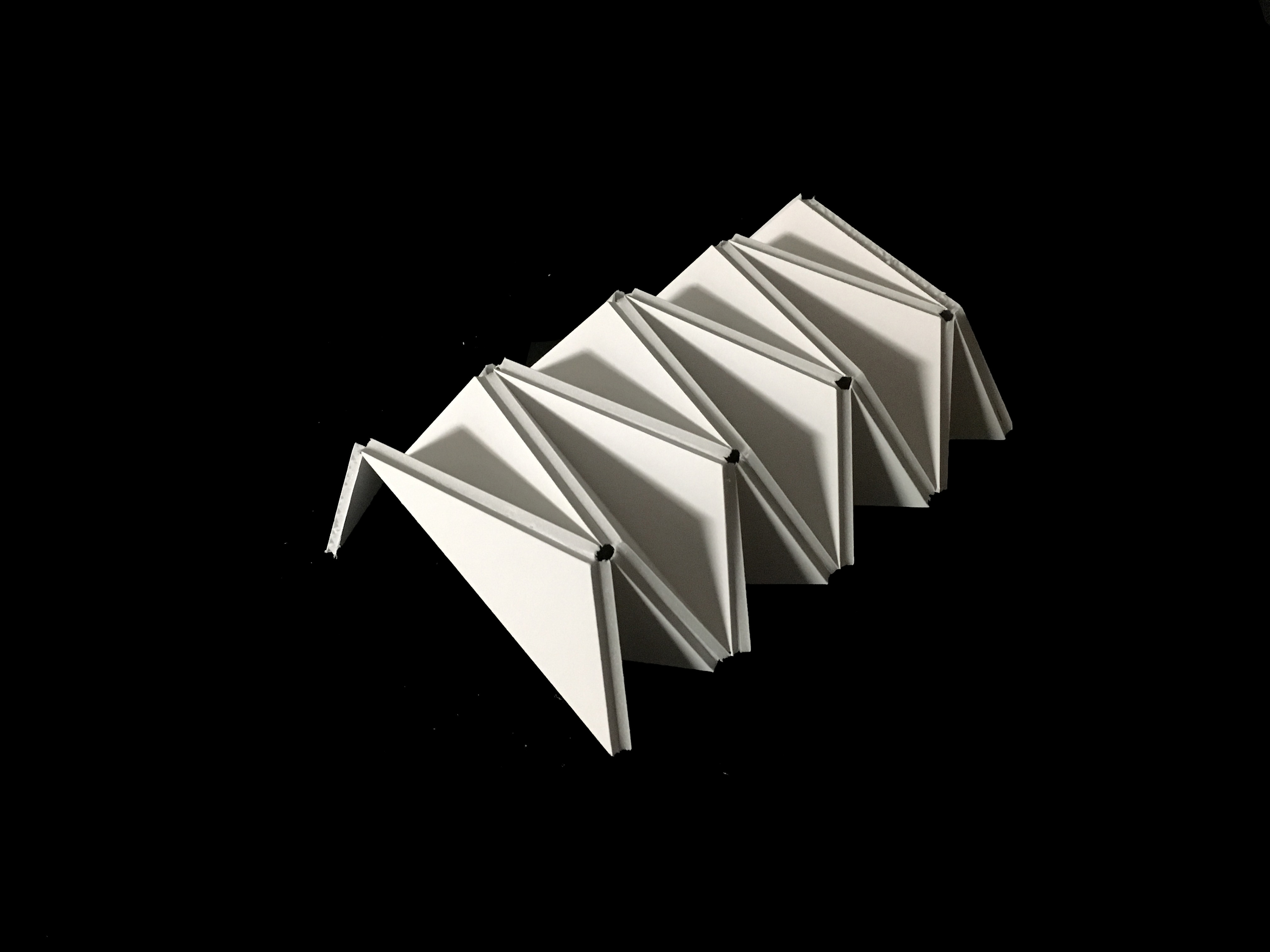

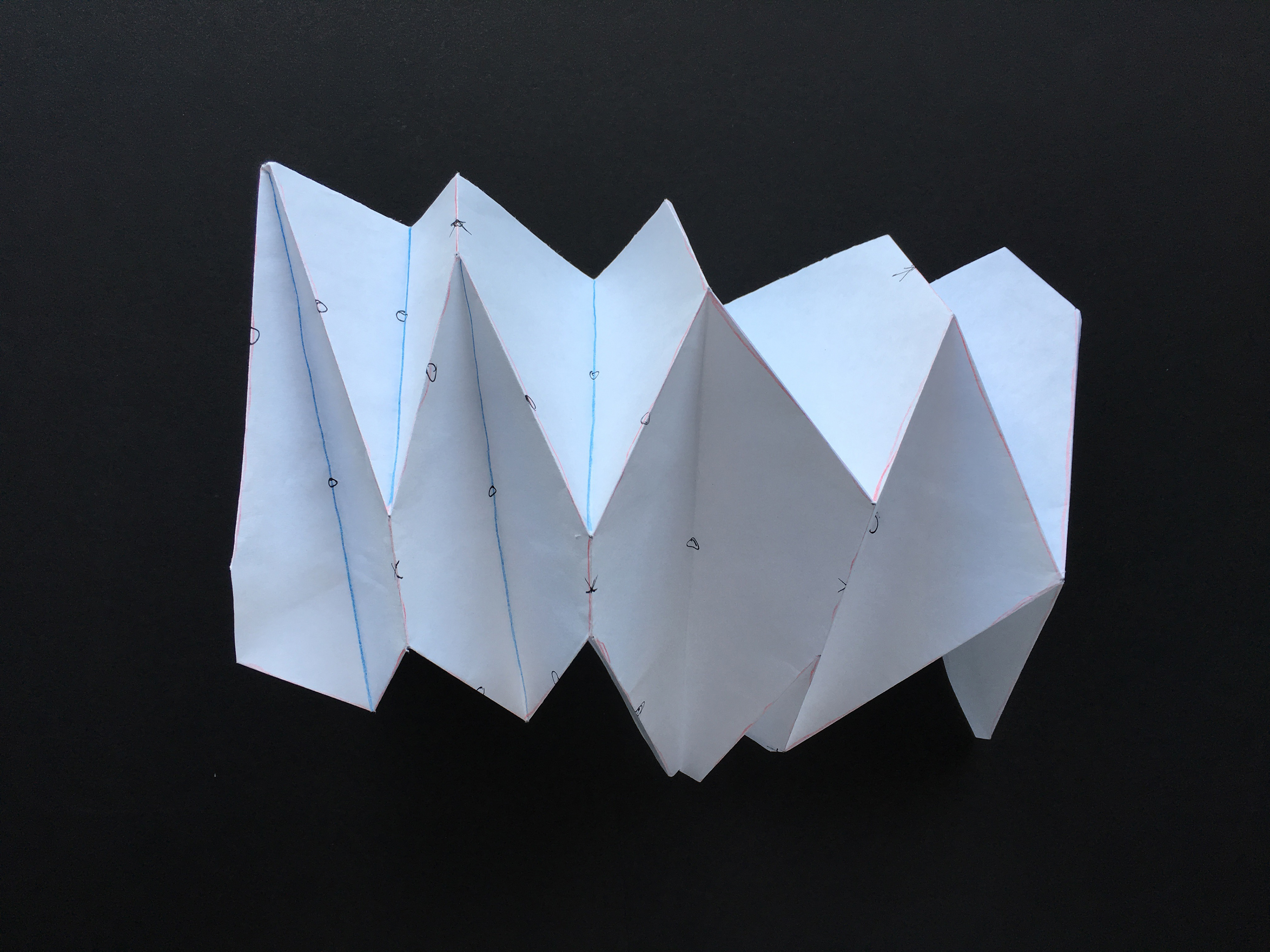

Paper Miura Tessellation Study I

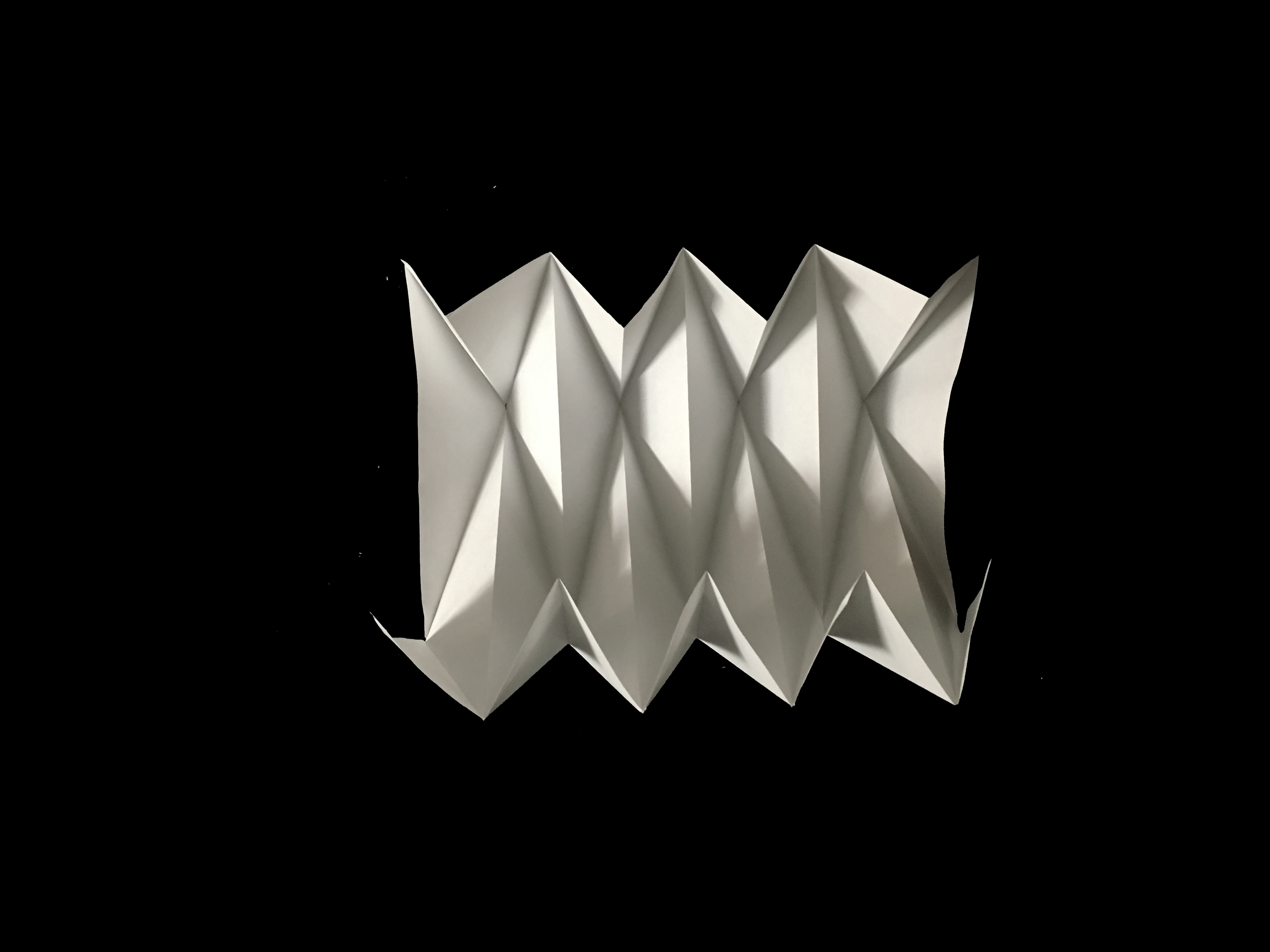

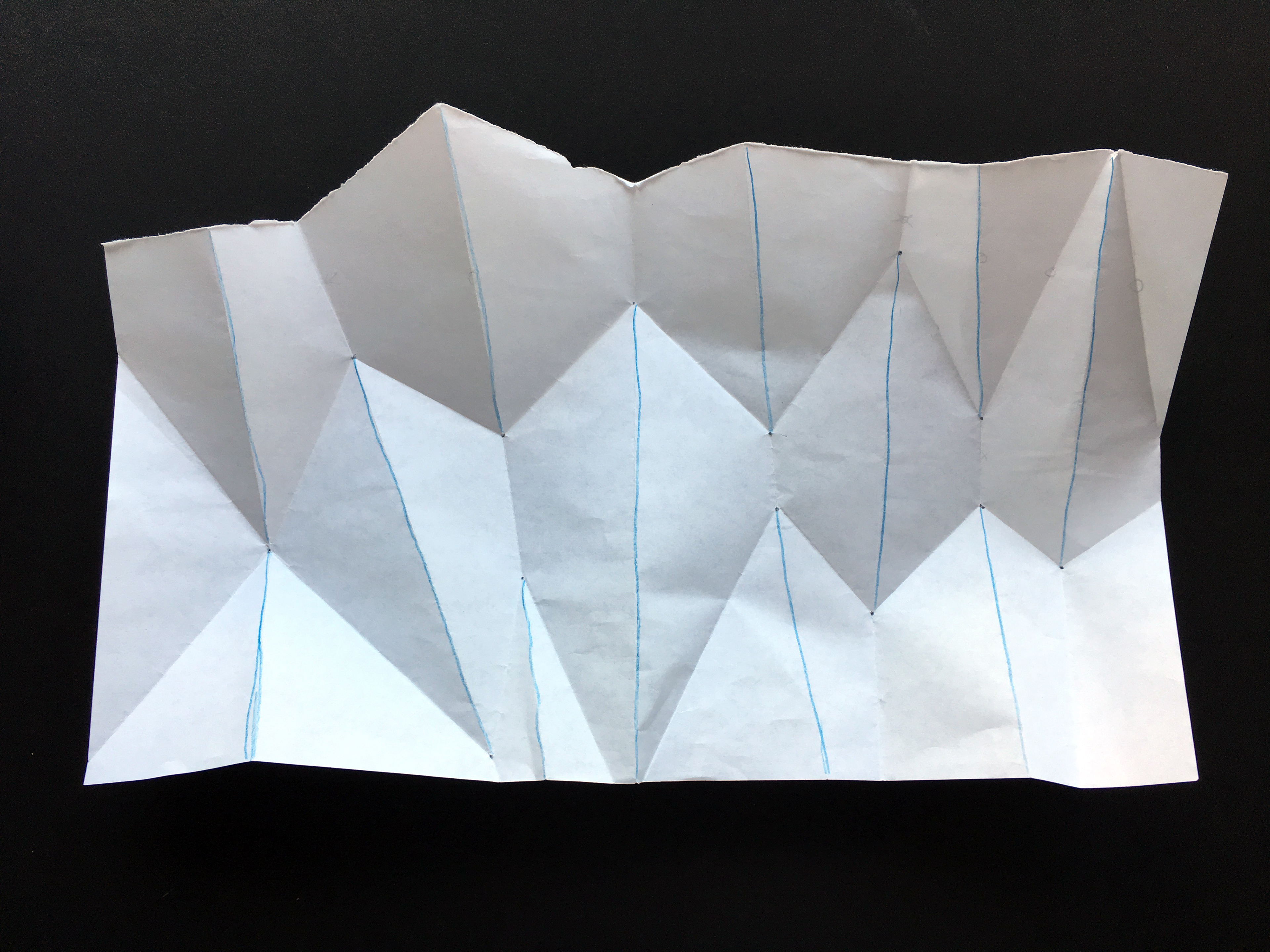

Paper Miura Tessellation Study II

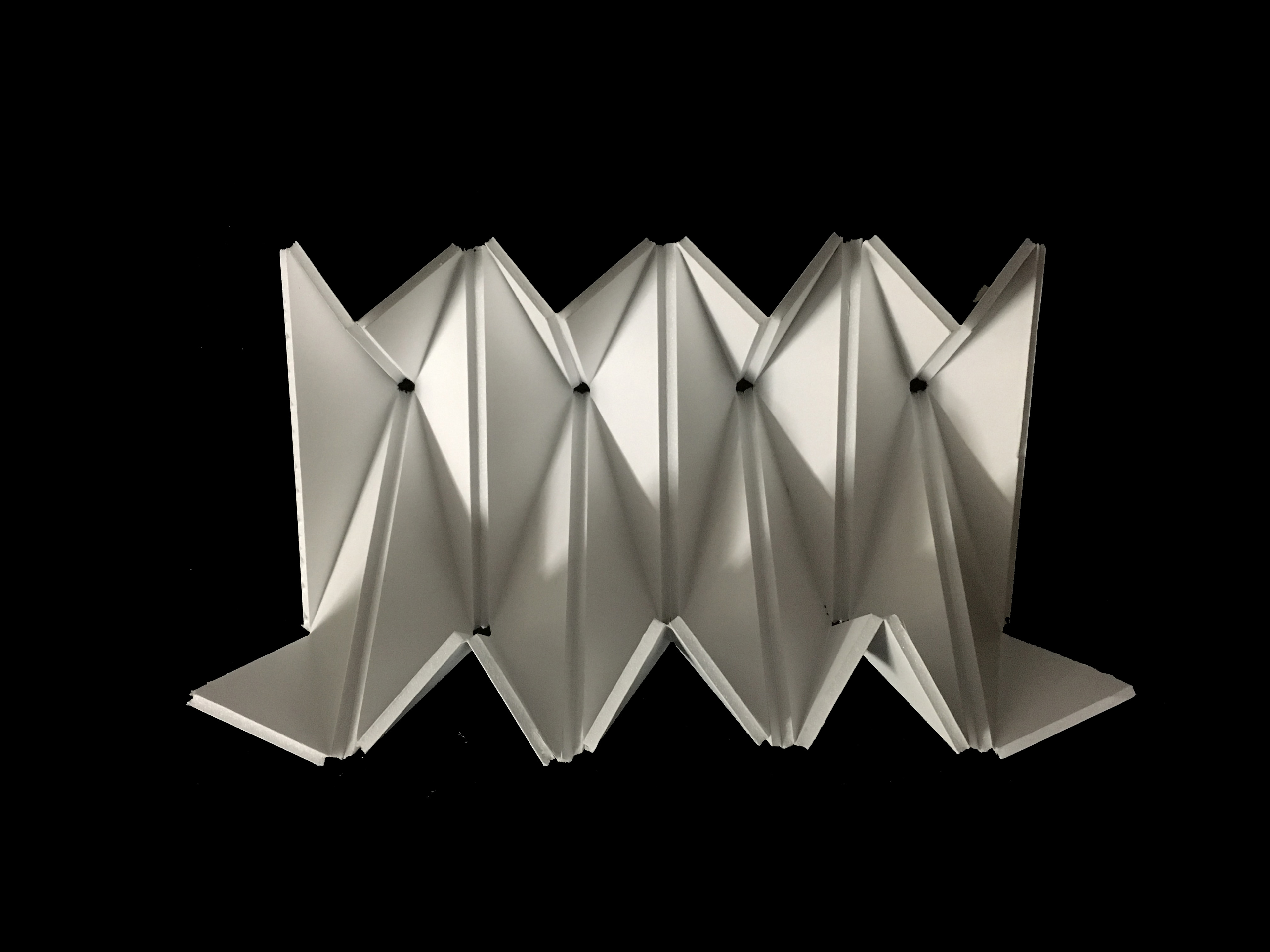

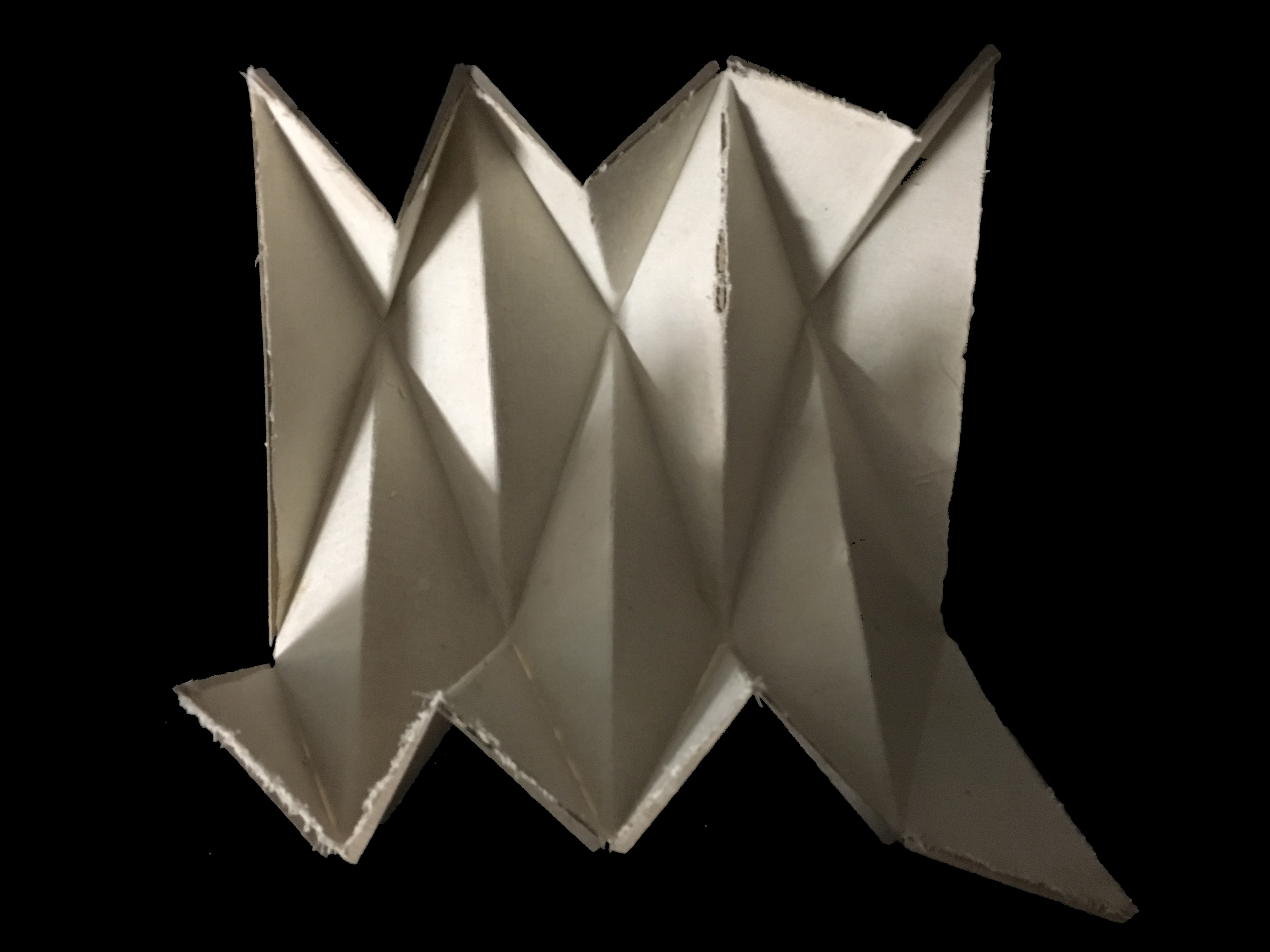

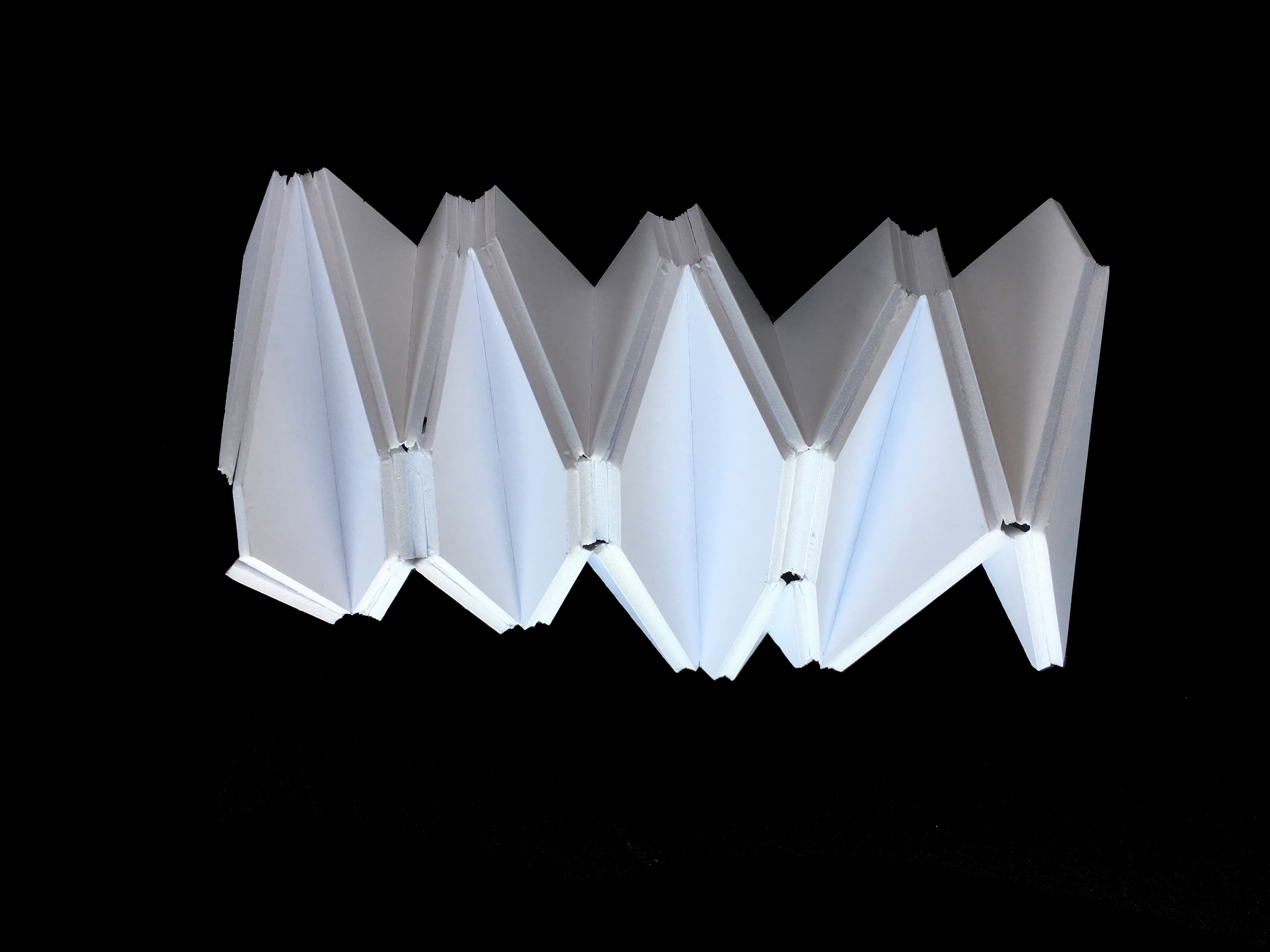

Foam Core Miura Tessellation Study I

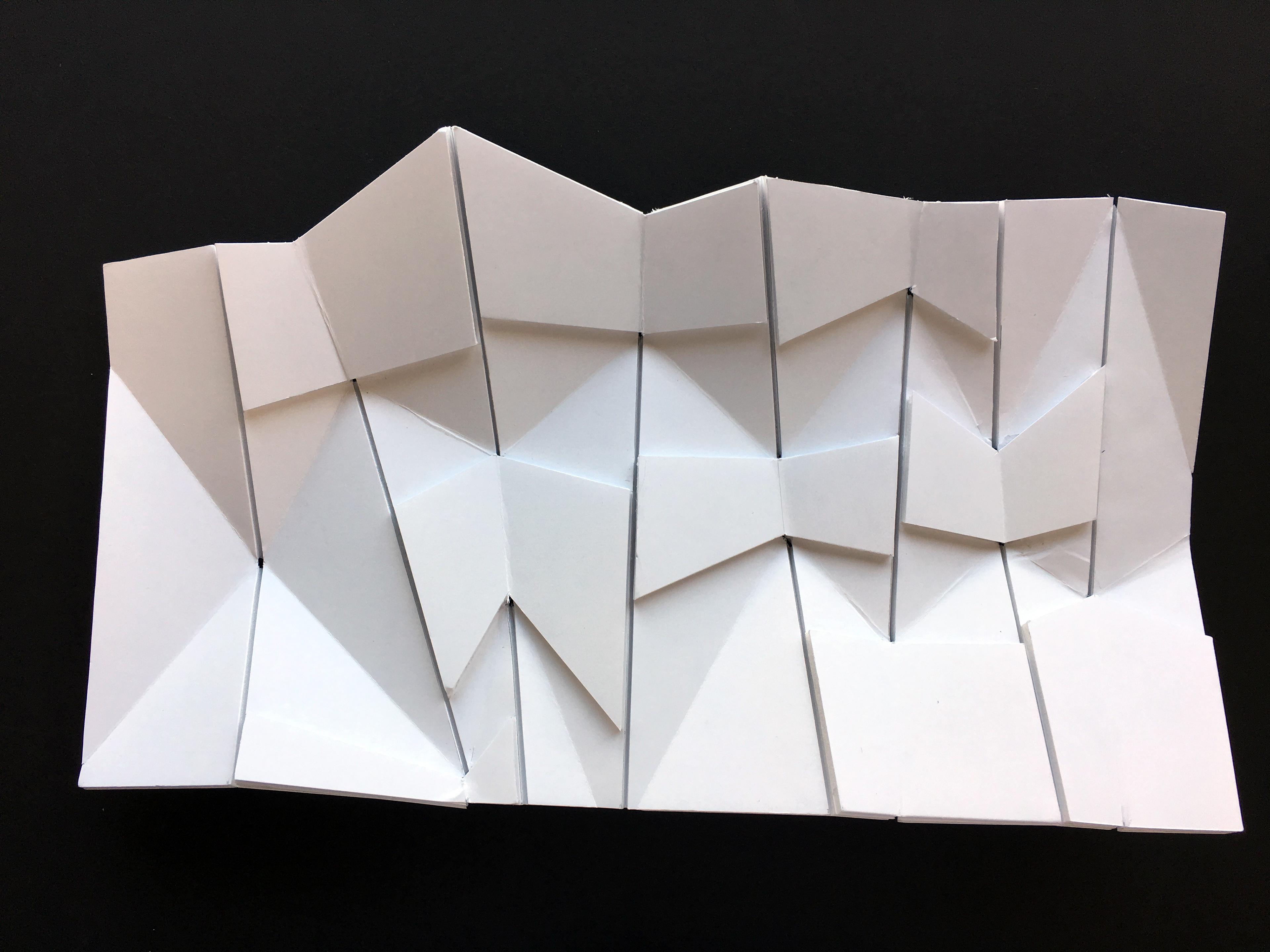

Foam Core Miura Tessellation Study II

CNC-Milled MDF Miura Tessellation Study I

CNC-Milled MDF Miura Tessellation Study II

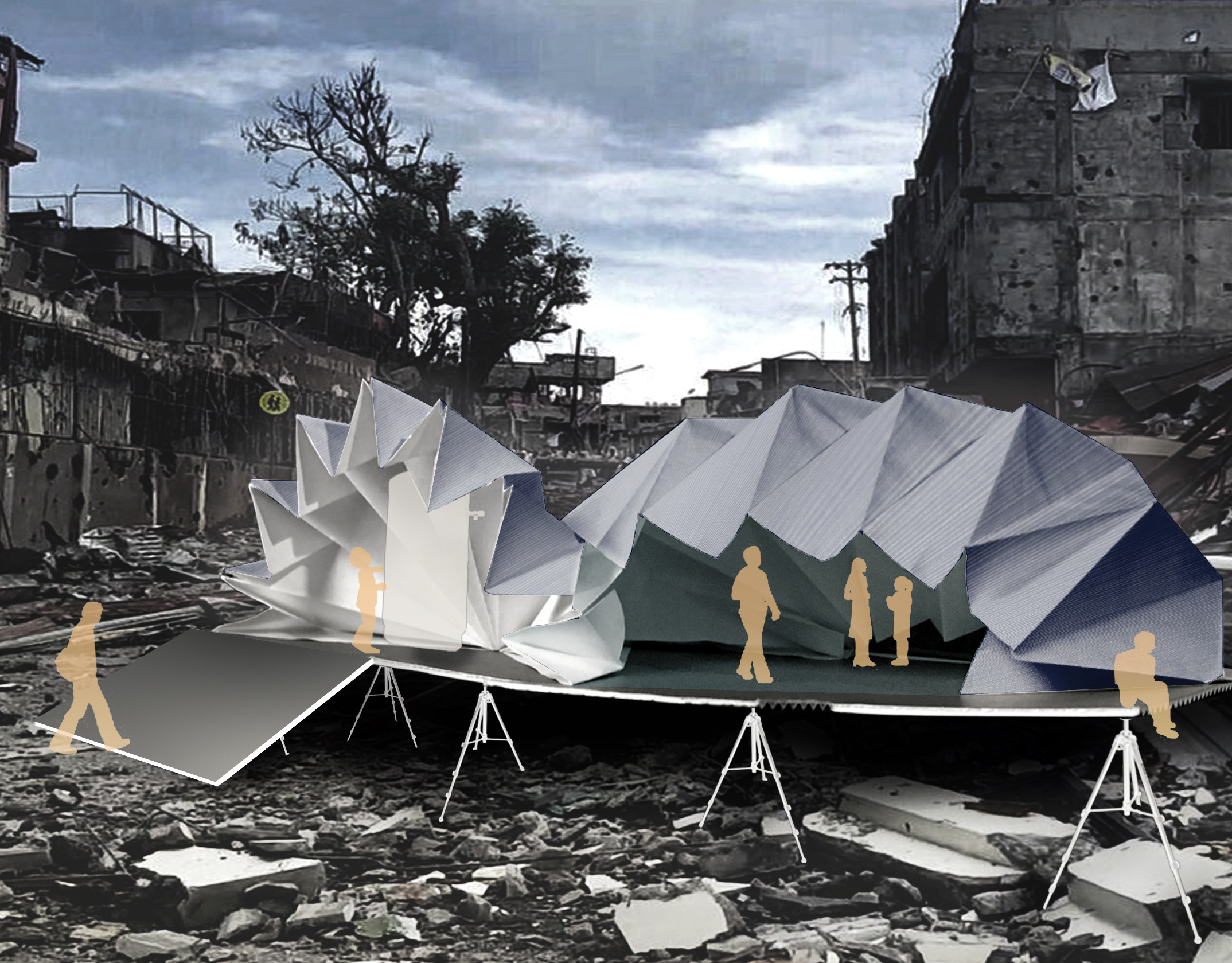

Miura Tessellation Application

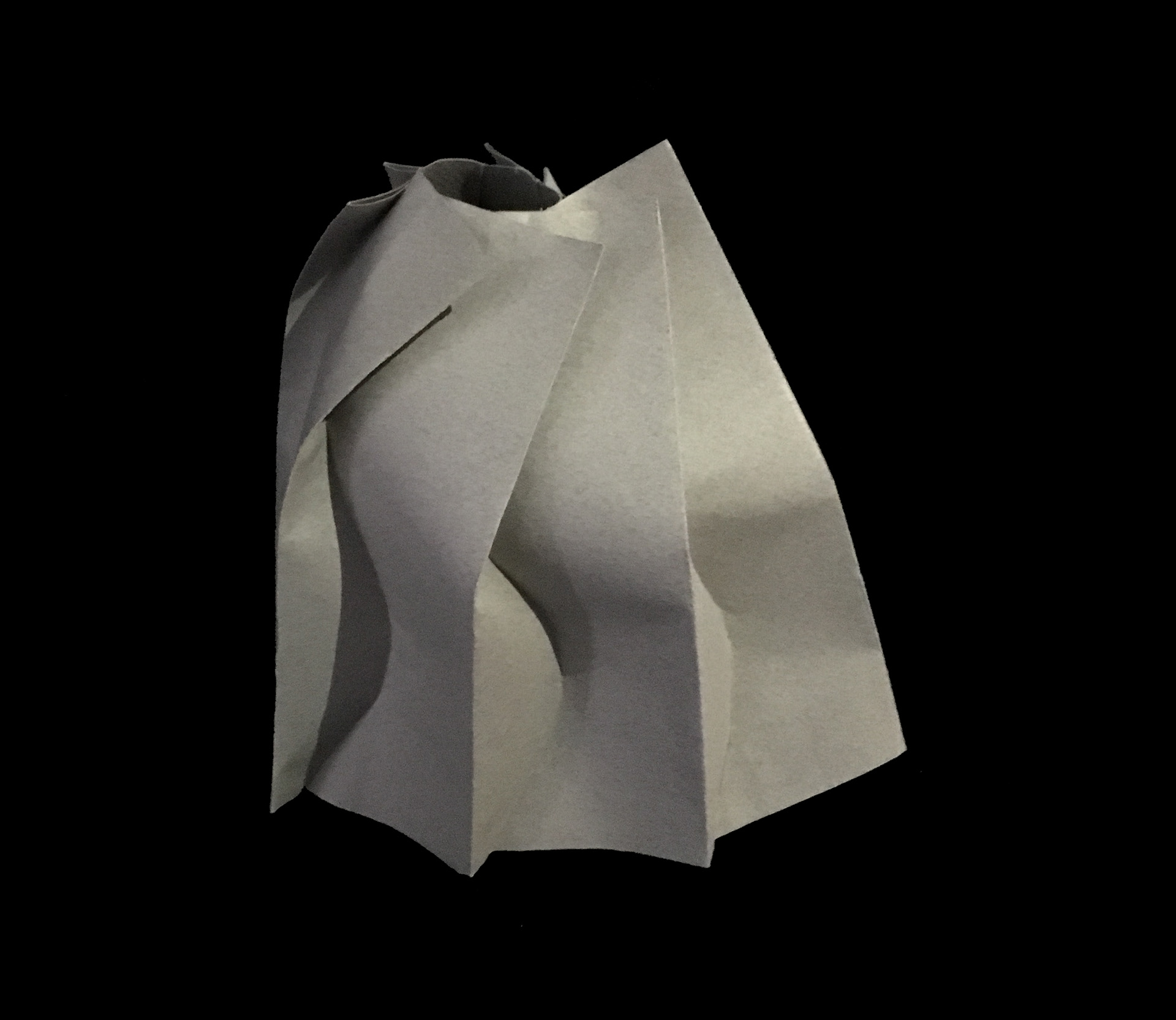

The above study was inspired by the application of the geometric logic behind the Miura tessellation in a more erratic and asymmetrical manner.

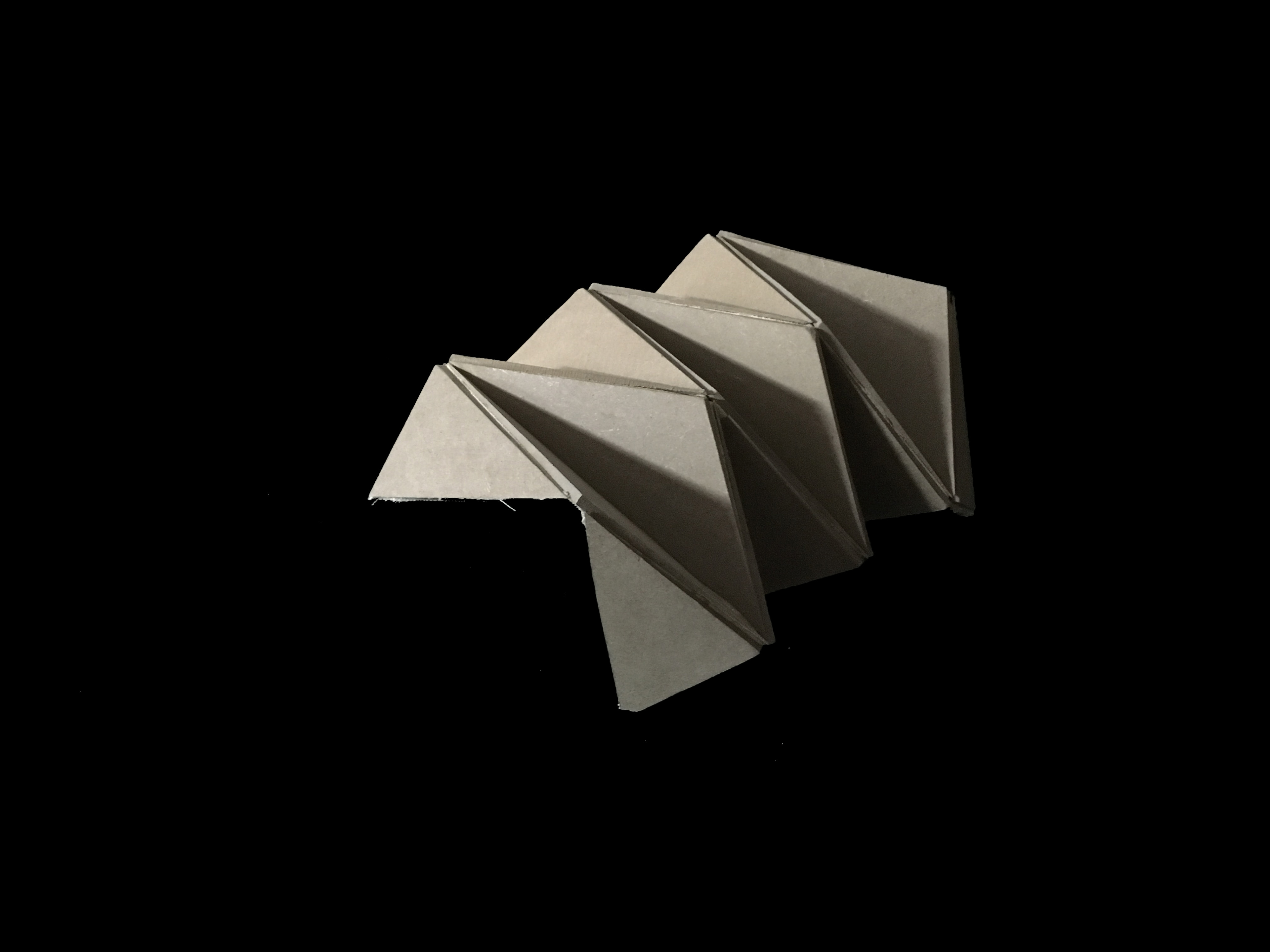

Paper Miura Tessellation Application I

Paper Miura Tessellation Application II

Foam Core Miura Tessellation Application I

Foam Core Miura Tessellation Application II

Rotational Folding Study

I have also experimented with rotational, curved folding, experimenting with asymmetrical forms using modeling software to generate the folding patterns.

Plan View

Perspective View

Rigid Folding Exploration