DE_CON: Deconstructing Blight

Deconstructing Blight deals with a multitude of issues and complex relationships that are implicit in the vocabulary utilized. The body of work executed this semester explores these relationships in regards to both what blight and deconstruction mean in the context of the built environment. Furthermore, the relationship between the two, in regards to the impact of physically deconstructing blight as well as conceptually deconstructing and performing analysis of urban blight in Pittsburgh. These explorations can then be related to one another and viewed from a more optimistic perspective in regards to how physical deconstruction can provide job opportunities and living wages for communities while also generating significant figures of tax revenue. In addition, as a more sustainable substitute for demolition, deconstruction of buildings can also prevent devastating impacts of exacerbated air quality for those in the vicinity of demolition work as well as divert significant quantities of material from landfills. The resulting vacant lots or building structure can then be build upon or renovated to boost the value of properties nearby. The lots can also be utilized for community projects as a resource for the community. In essence, the relationship between blight and deconstruction can be a generator of opportunity both in compelling social and economic change for those in areas of concentrated poverty, as well as impact the environmental and health related consequences of demolition waste.

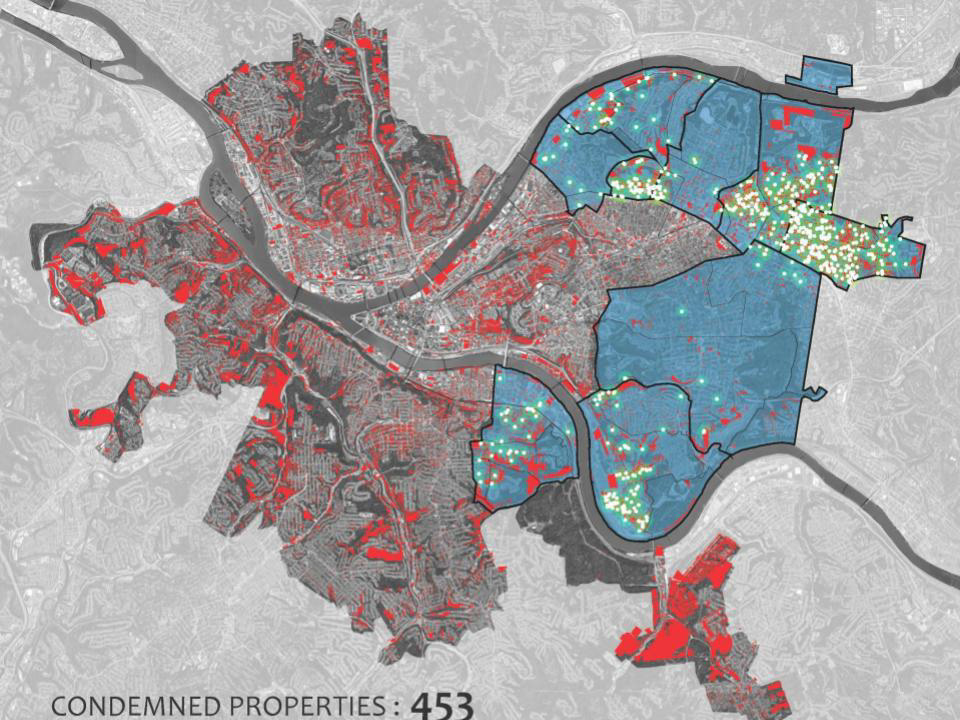

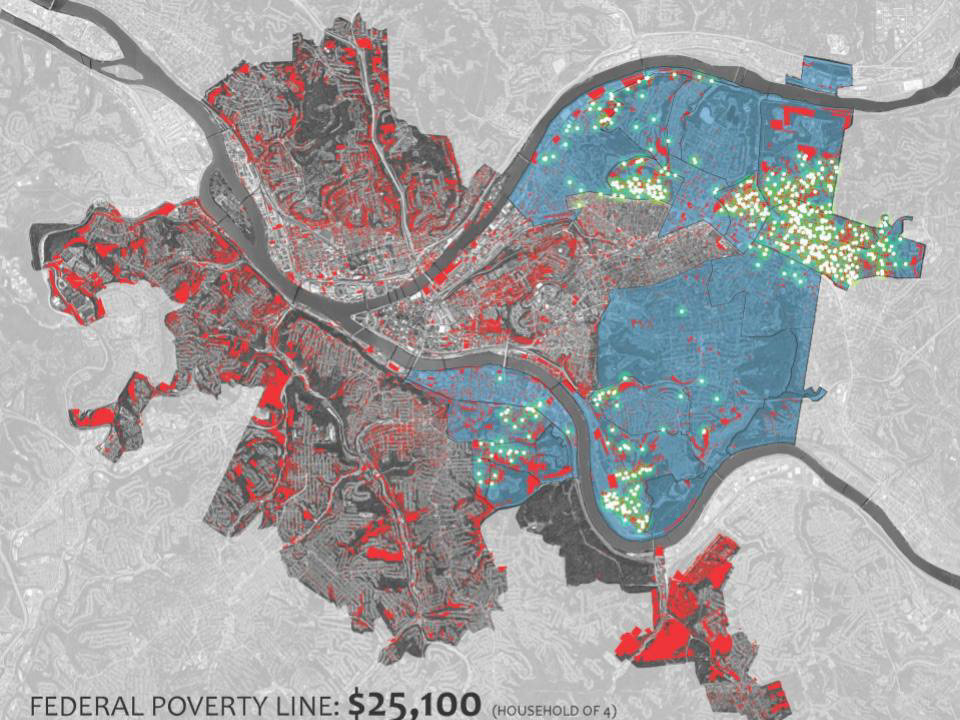

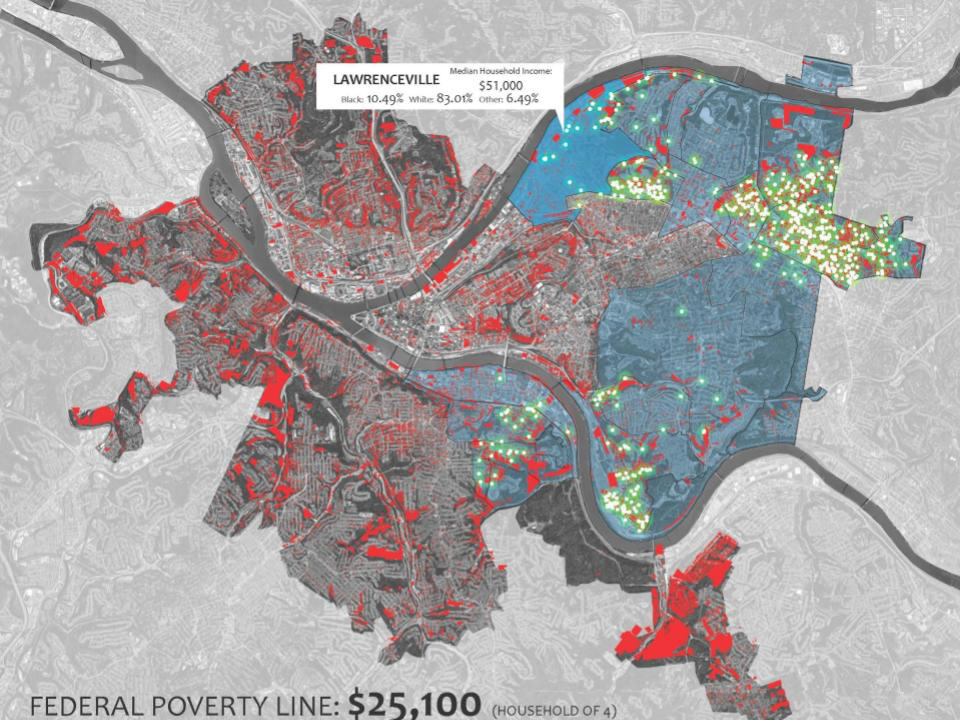

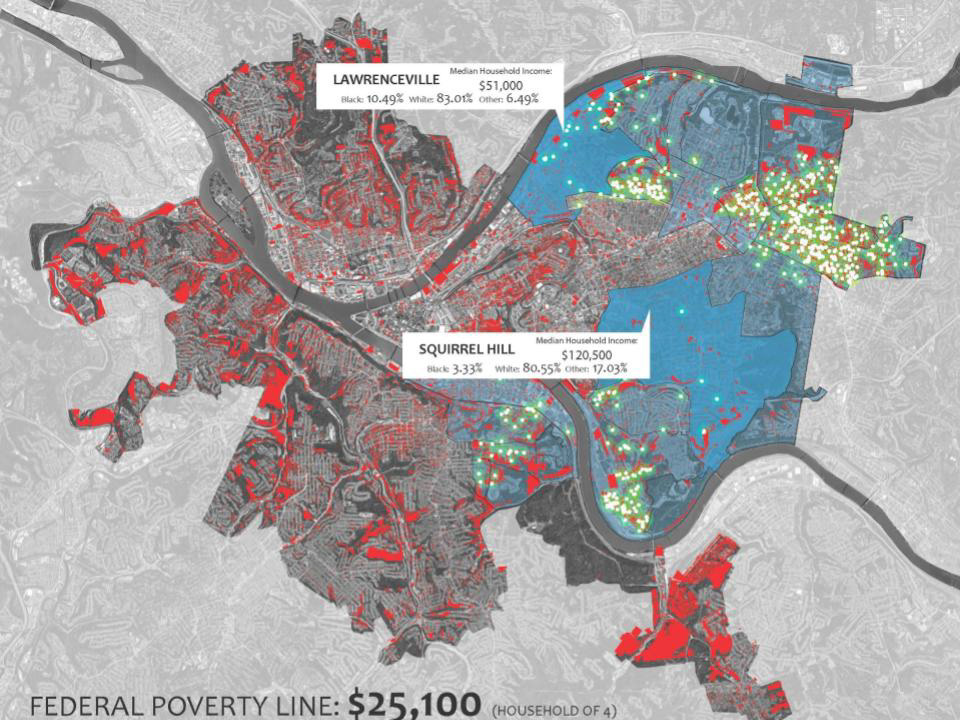

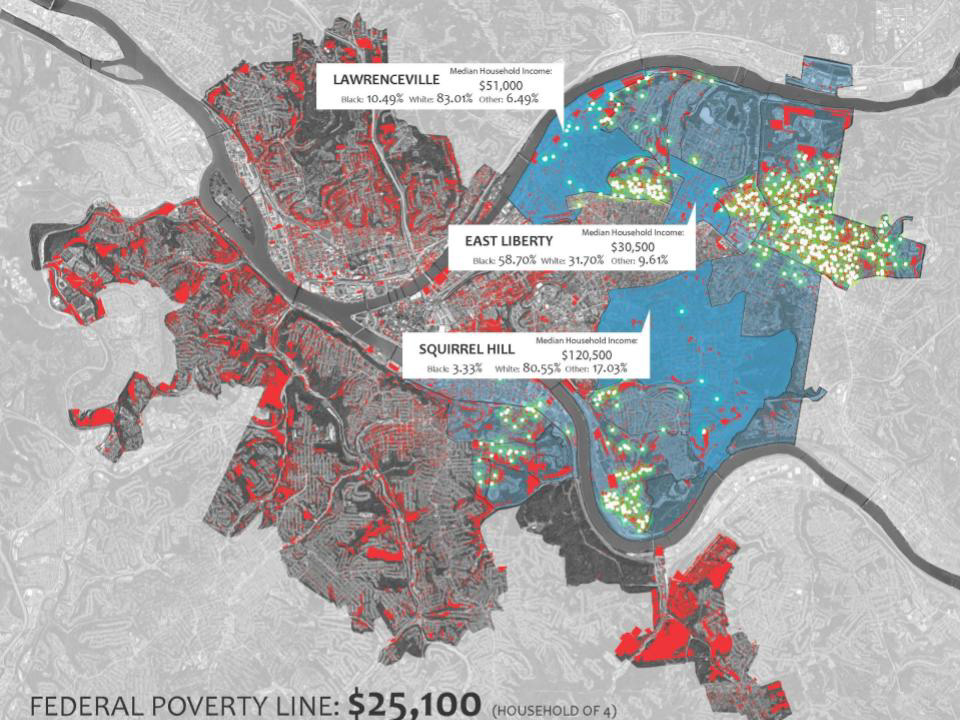

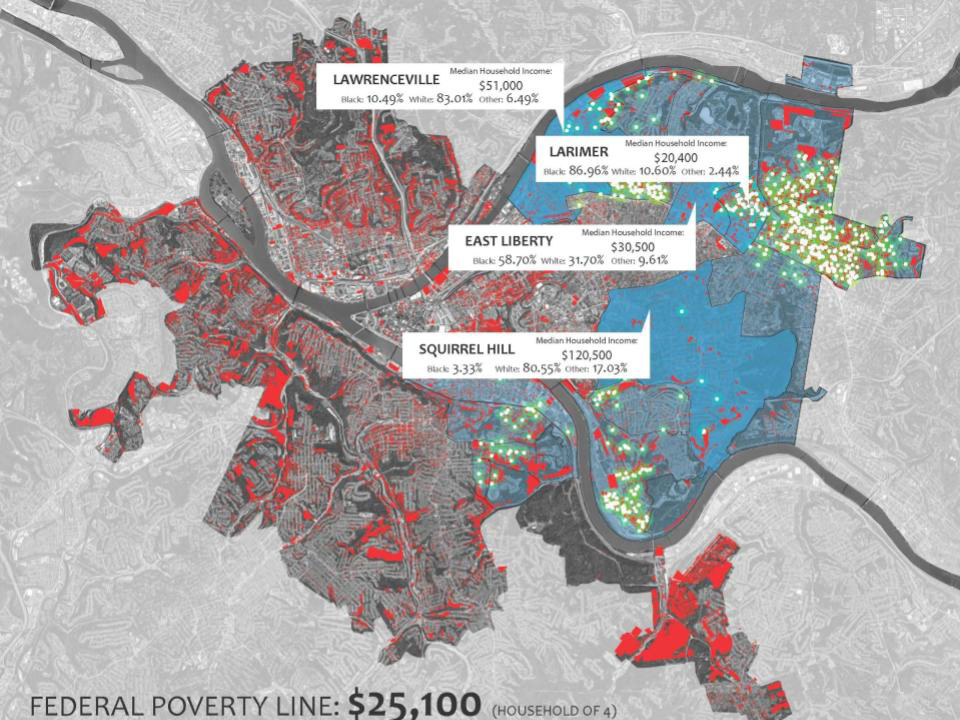

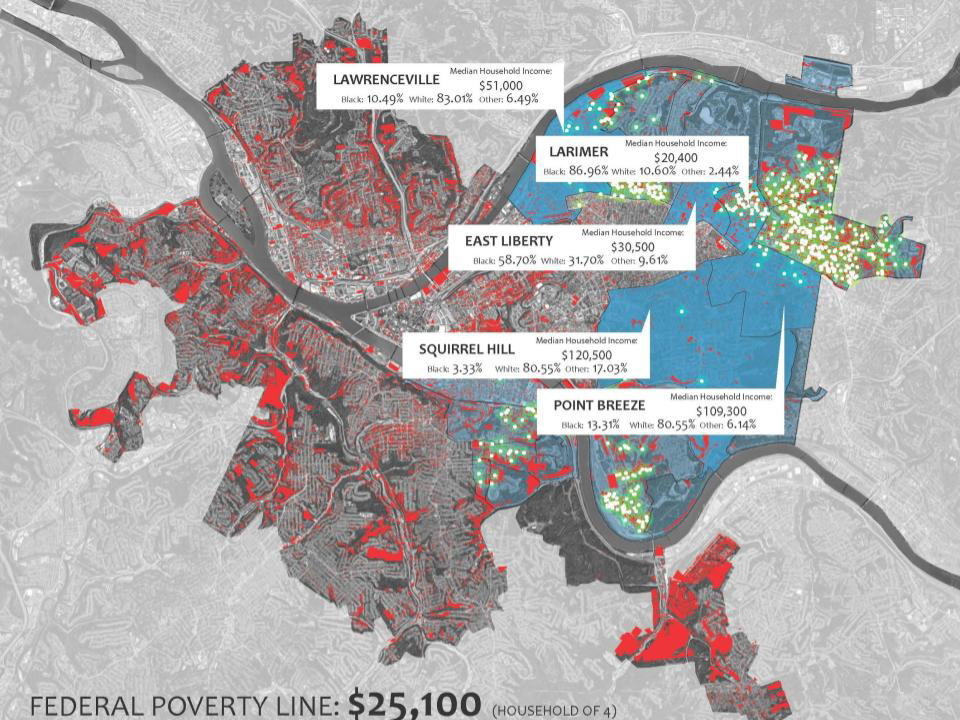

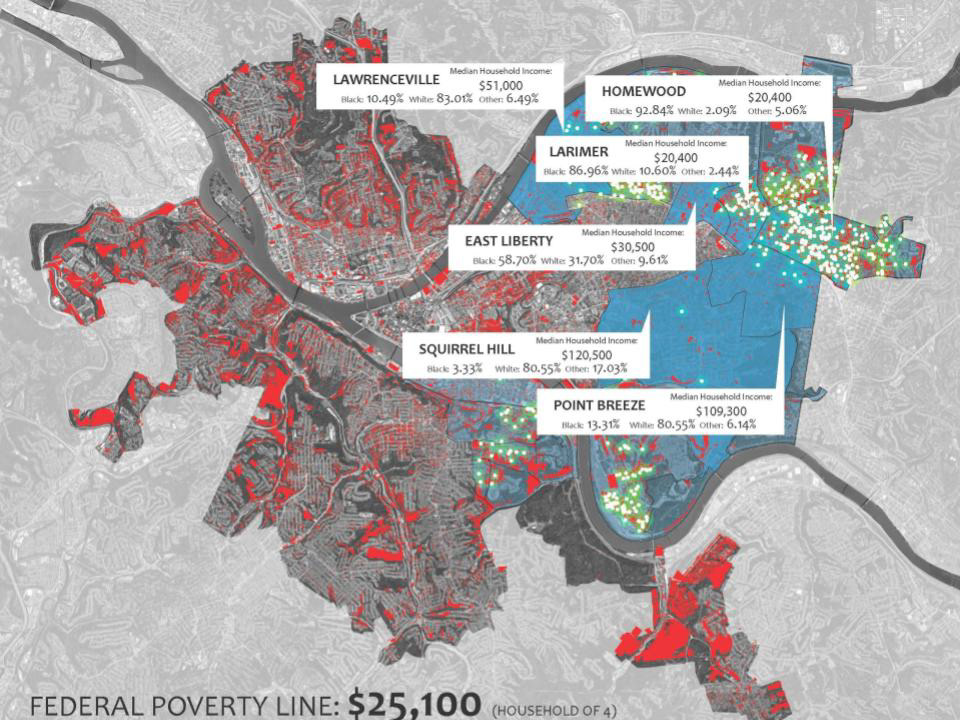

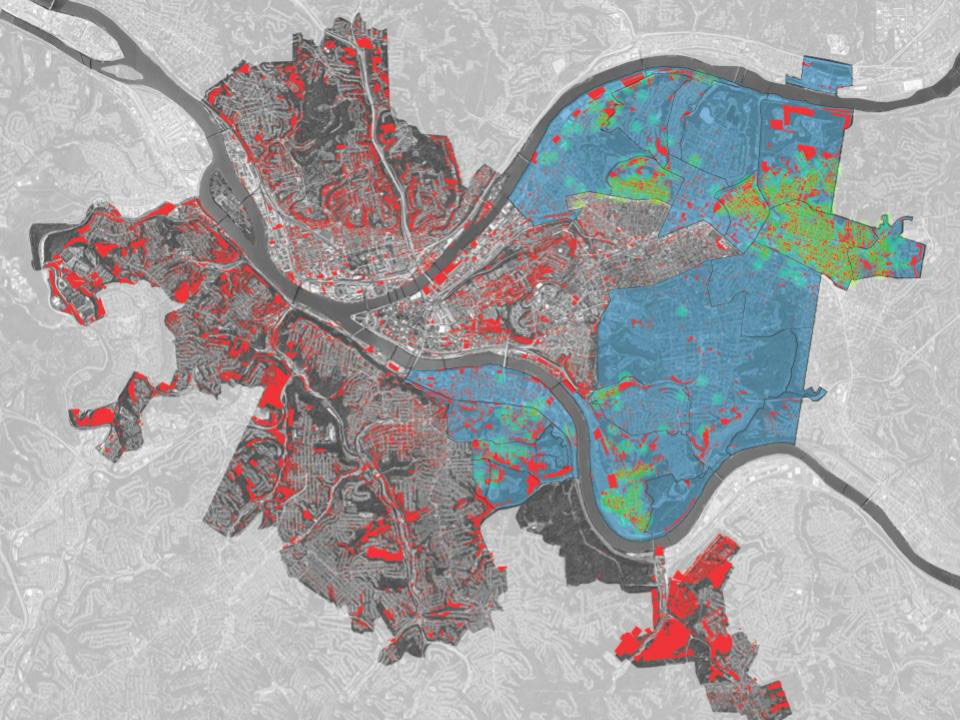

Mapping Blight

Deconstructing blight in the conceptual sense of breaking apart the story of blight, understanding its scale and impact, and how to leverage blight to affect positive change.

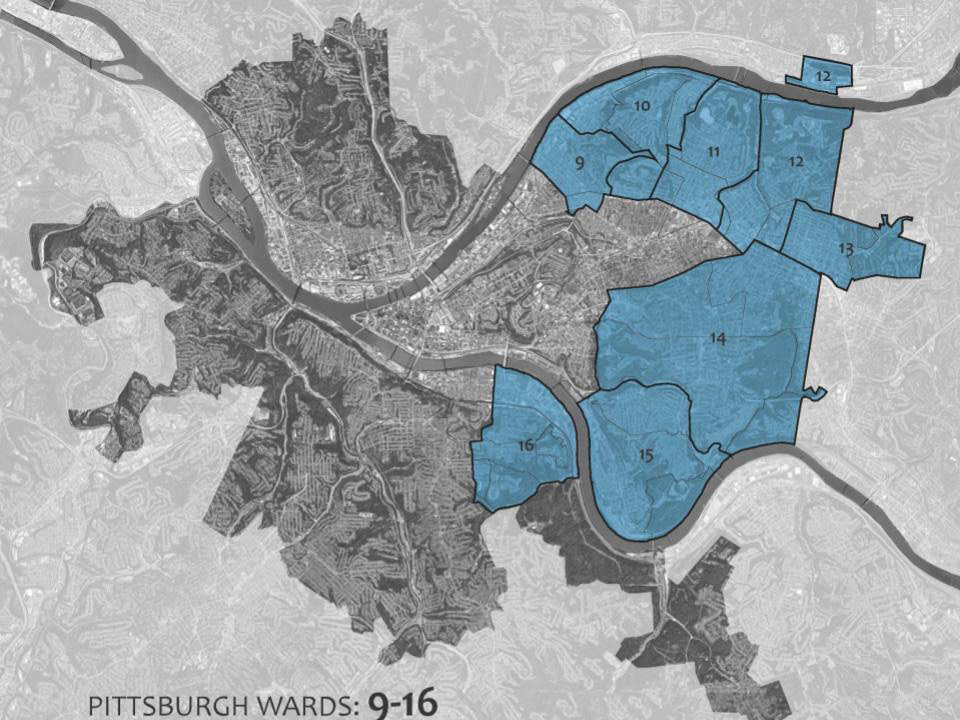

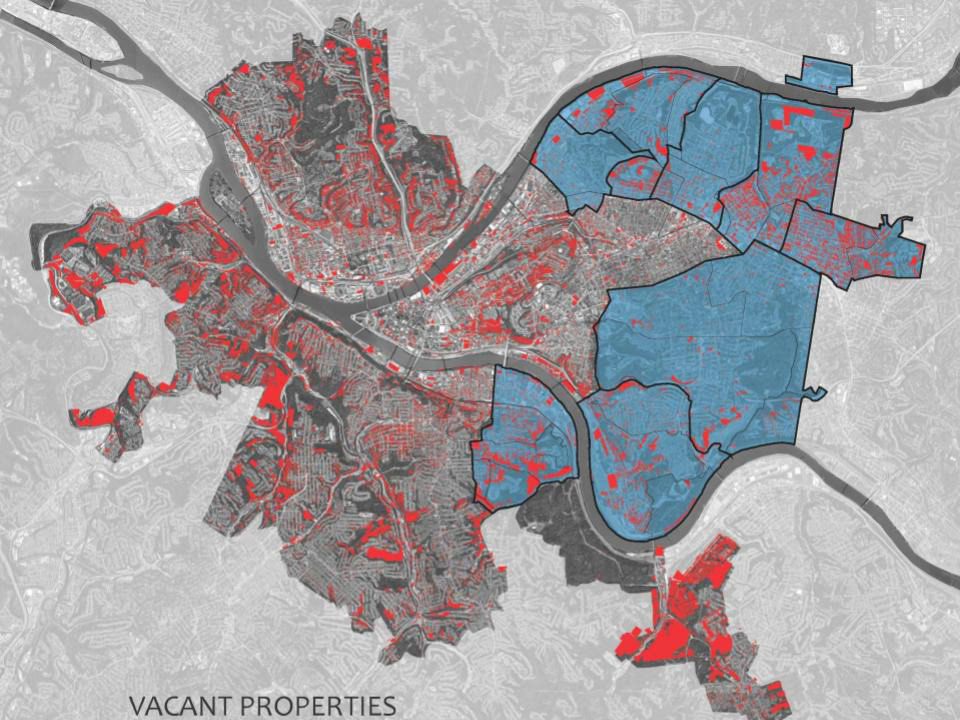

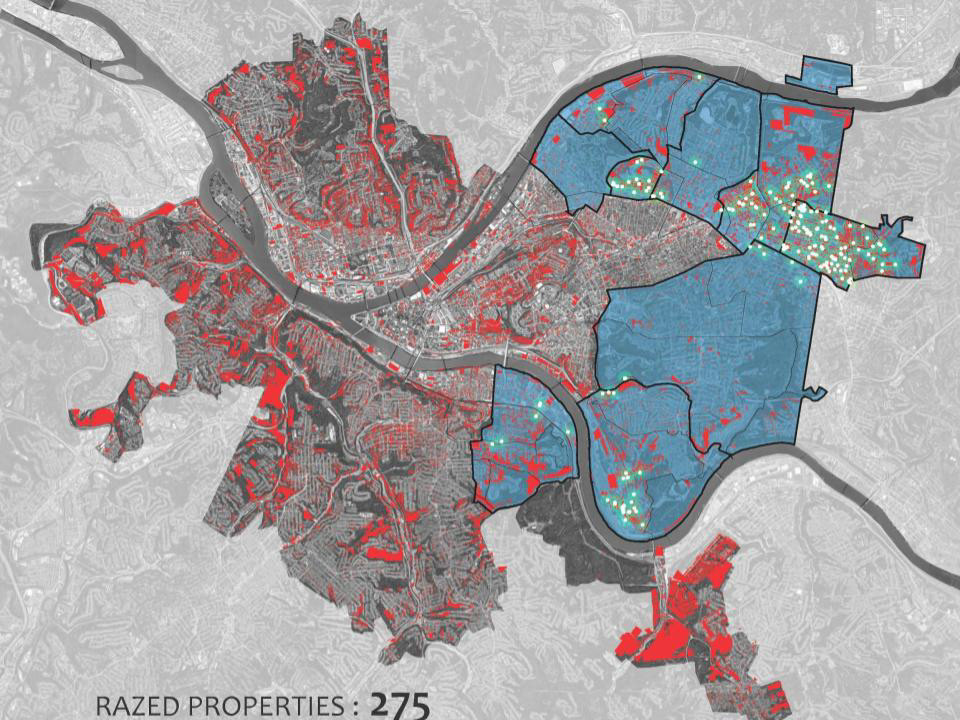

In collaboration with IDeATe, this project assigned a series of wards to a group to then explore issues of blight on various scales, ultimately aiming to tackle issues of materiality and quantity in regards to condemned buildings. The project also called for the use of Autodesk Recap to analyze condemned building(s) to then better understand, calculate, and reinterpret potential positive futures for the structures in regards to their materiality, their context, and their neighborhood. My group took ownership of wards 9-16 and decided to hone in on the greatest disparity of wealth, most severe demographic singularity, and most comprehensive portrayal of the impact of de facto and especially de jure segregation in the past, Homewood and Point Breeze. Point Breeze, one of the most affluent neighborhoods, is a mere 5 block widths away from Homewood, one of the the United States’ most devastatingly disinvested neighborhoods. This stark contrast immediately is followed with the straightforward analysis of median incomes and crime rates, yet the architectural aspect of the issue perhaps shines a difference light, that the plethora of vacant lots in conjunction with their resource of condemned buildings can be implemented to provide a more positive outlook for Homewood.

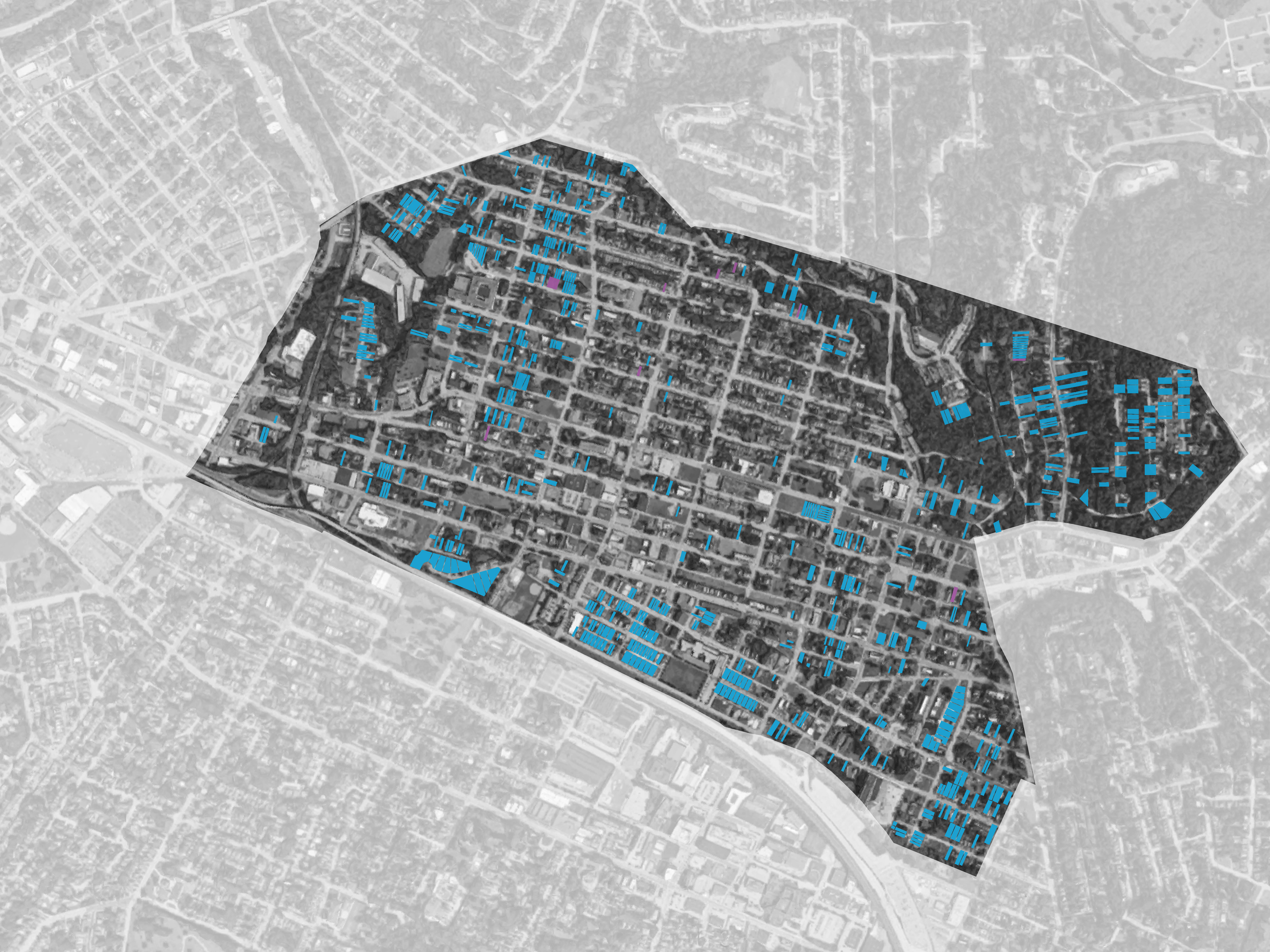

Homewood Building Construction Type Map

Through the following progression of material maps, it is possible to begin understanding the general composition of Homewood in regards to material or vacancy. From this, it is clear that there still is much potential in regards to land that can be purposed for uplifting communities, and also that the abundance of contextual brick and wood construction can serve as job opportunities for members of the community for developing valuable skills.

Vacant Lots

Brick Construction

Wood-Frame Construction

Masonry Construction

All Construction Types

Photogrammetry Study

To better understand the spatial and dimensional qualities of urban blight, we conducted a photogrammetry study to create a model of the selected structure. I utilized a locally run photogrammetry software called 3DF Zephyr (the free version) to process scans of 50 photos at a time. This software, after running the scan, shows which photos were actually used and paired in the resulting scan. As a result, I was able to filter photos out in this way, slowly narrowing in on a curated selection of photos which would produce a better scan. Then, I ran Autodesk Recap scans to test the photo groups, eventually settling for a scan with some gaps. Despite the imperfect quality of the scan, when considering the fact that the building was elevated above the street plane and attached to three other buildings on one side as well as the inability to walk around the building and on the property for privacy reasons, the scan is successful in capturing, to a decent degree of reality, the site. With the resulting scan, I generated an animation which scrolls around the property and not only in its state and general appearance, but also in regards to its construction and what materials can potentially be re-purposed should it be deconstructed. This offers a more optimistic perspective to the issue of blight and condemned buildings which are often associated with bleak future prospects.

In venturing out into the neighborhood to obtain the source material, I had the opportunity to engage and speak candidly with residents in the area who shared their thoughts about their fond memories of different times in the past, about the changes they had experienced over time, about their frustrations about the past, and about their hopes for the future.

DE_CON 01: Solar Decathlon House

Deconstructing blight in the physical sense of understanding how to take apart buildings, gathering data on the yield of deconstruction of different materials, and experiencing the energy input necessary and complications of deconstructing a building

The building that was deconstructed for this project was the 2005 Solar Decathlon submission, which was a collaborative project between Carnegie Mellon University, the University of Pittsburgh, and the Art Institute of Pittsburgh. For more information about the project, follow this link!

The 2005 Solar Decathlon House also was home to a prototype of the RE_VIEW wall system which was designed and developed by an interdisciplinary team of collaborators previously. For more information about RE_VIEW, its context, team, and intent, follow this link!

Deconstruction Example: Interior Wall & Ceiling Cladding

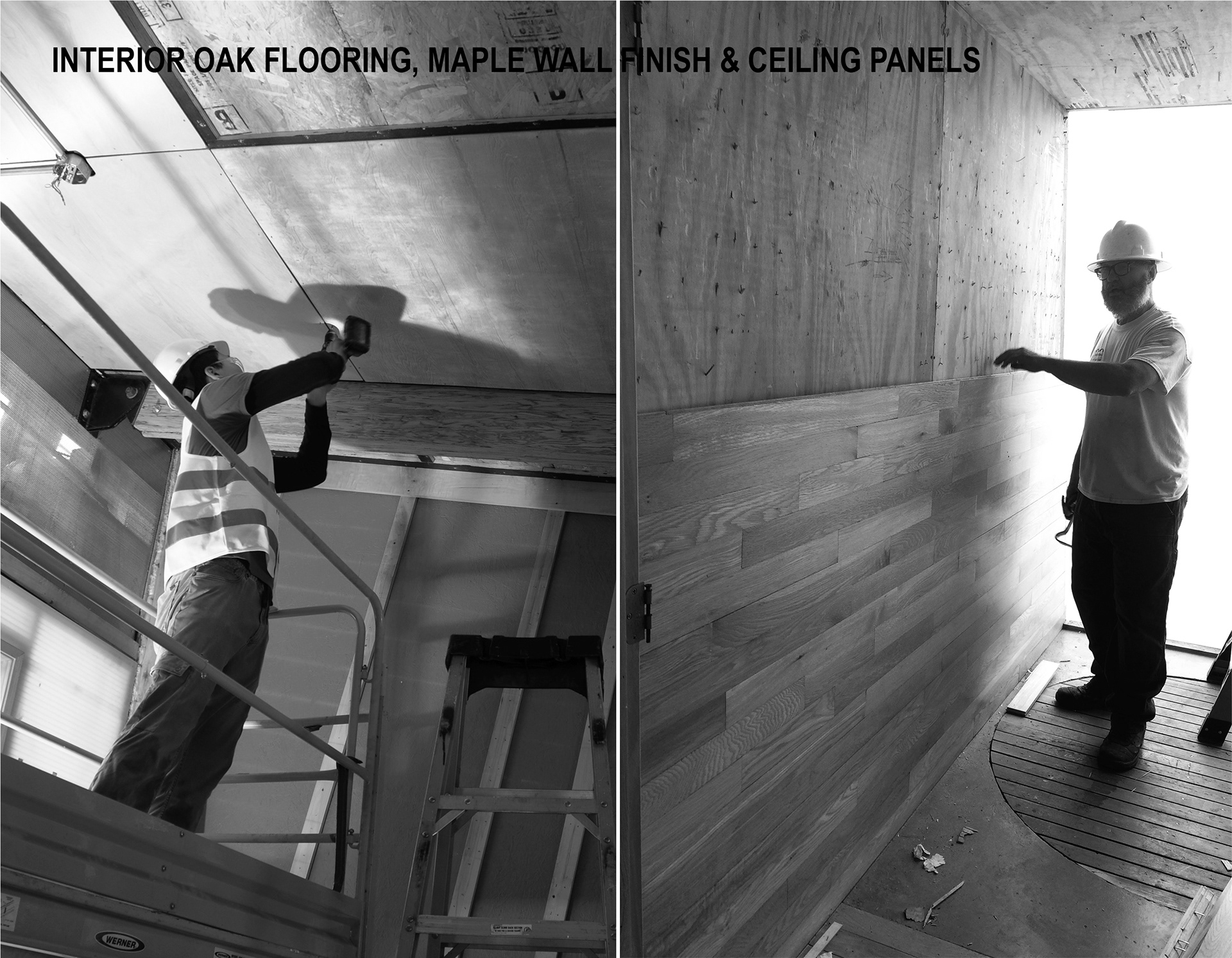

The deconstruction of the interior wall and ceiling cladding was fairly straightforward. An assortment of power drills with Square #02 bits as well as some supplementary flat bars, hammers, and chisels were sufficient for the job. With variation in people's availability, sometimes it was done individually, but the task was significantly easier with two people on a scaffold or with two ladders to increase reach, allowing the team to unfasten more screws more efficiently and safely.

One instance occurred where the deconstructing team on site did not know whether the ceiling panels were glued on or just screwed on as the plywood did not come off after the screws were unfastened. Funny enough, it turned out that the plywood panel we were testing happened to be an outlier that was stuck on because of some paint, but this instance portrayed the difficulty that can be experienced with even a very basic assembly detail. Furthermore, considering other more intricate systems, for example the RE_VIEW wall system that was embedded in the building, the project was determining the delicate balance between taking extreme care to preserve the materials we were extracting and forcing materials apart to save time, which differed greatly for different materials/systems.

Deconstruction Example: Mechanical Systems

The deconstruction of mechanical systems is quite like a puzzle, where by knowing a couple key principles, one can attempt to figure out the best way to deconstruct a system. The main principle, at least for plumbing, was to avoid cutting pieces at the joints so that washers/nuts/ hardware would not get damaged and risk rendering the entire connection of the pipe useless. Furthermore, when cutting along the length of a pipe, it is important to remember to keep as long of a length as possible intact so that it can be more easily reused.

In regards to the electrical system, the main issue in this case was that the sensors had to remain in one piece and not be cut so that they could be reused again. Besides that, the wires generally are going to be recycled a opposed to being reused immediately so it is completely acceptable to cut them if it is inefficient and unproductive to waste time untangling it. On the first day, Jake and I tagged along with Brian and Bill from Construction Junction to disassemble the first floor mechanical systems. By the next session, Jake and I were able to disassemble the mechanical system in the loft on our own by talking through the process of figuring out where to cut.

DE_CON 01: Deconstruction Documentation

Deconstructing blight in the representation sense of learning the environmental/economic/social benefits of deconstruction over demolition, and advocating for deconstruction in the context of providing living wage job opportunities through job-skills training as well as in the context of mainstream building take-down practices by prototyping a regulatory documentation set that could be submitted for permitting in an urban context.

Deconstruction Documentation Set & Photography/Film

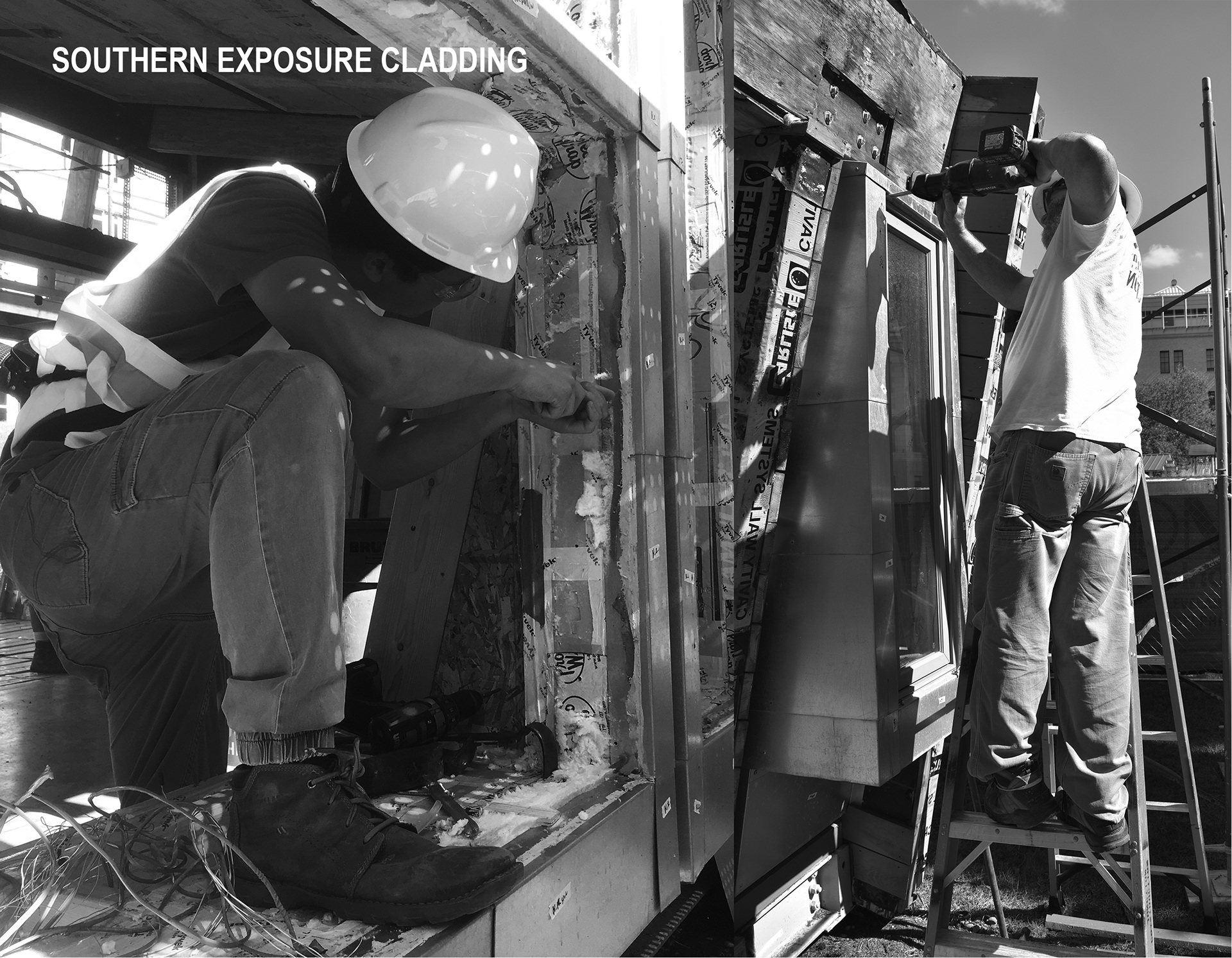

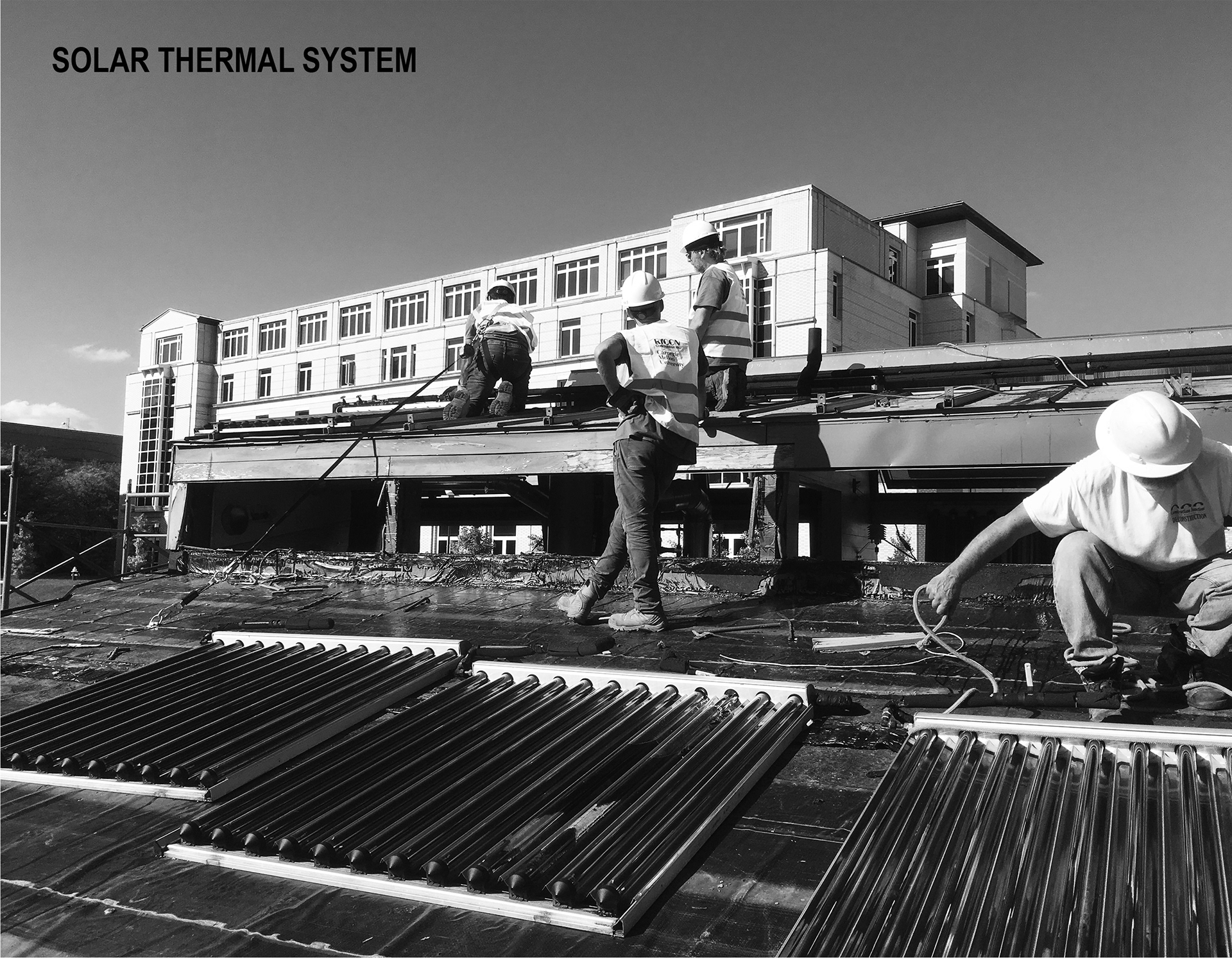

Throughout the process of deconstruction, documentation through constant drafting as well as through photography and videos has been crucial to serve as a reminder as to how the building was taken apart. Furthermore, at times, an image of people interacting with materials can speak much louder and clearer than an exploded axonometric or isometric drawing. By combining both mediums, it is possible to portray the tectonic properties of the built structure while also showing the human side of how the building was taken down. In addition, as DE_ CON 01 was a pilot deconstruction project, being able to refer back to photography and film of all kinds was critical to being able to perform an analysis of what took place to understand what aspects of the project could be improved for the next project. This became readily clear when trying to understand what material was taken off, what happened to it, and how much labor it took to achieve those processes.

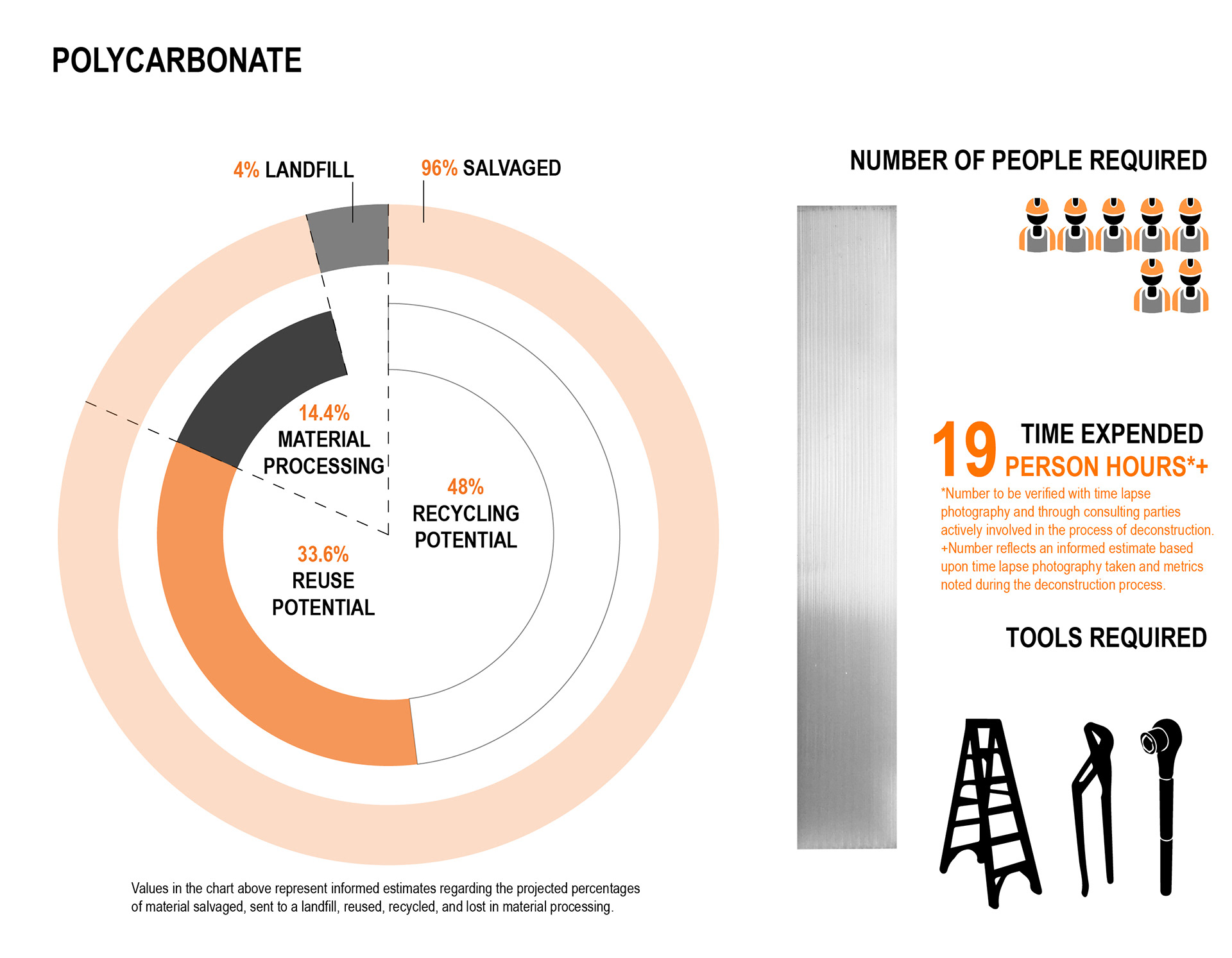

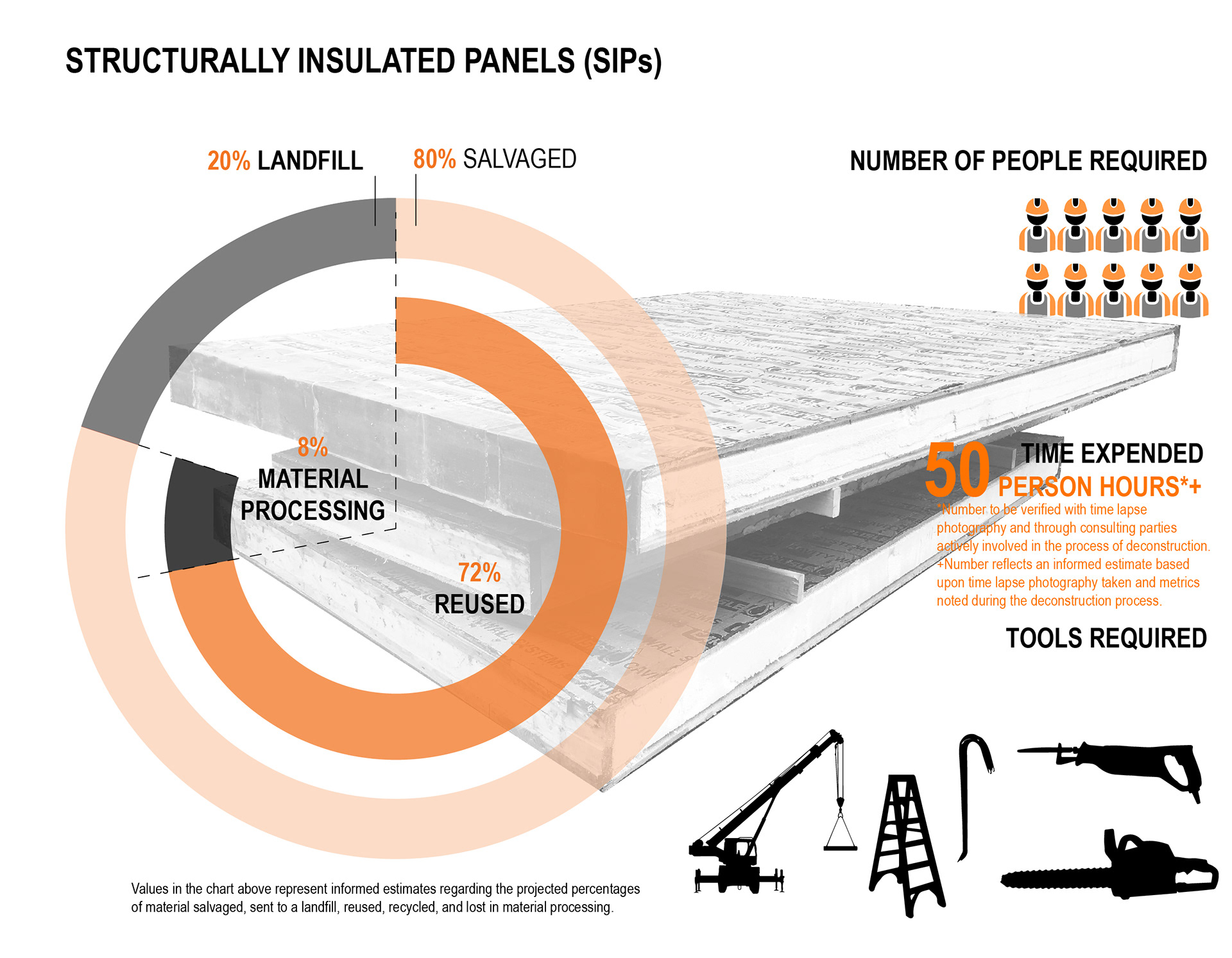

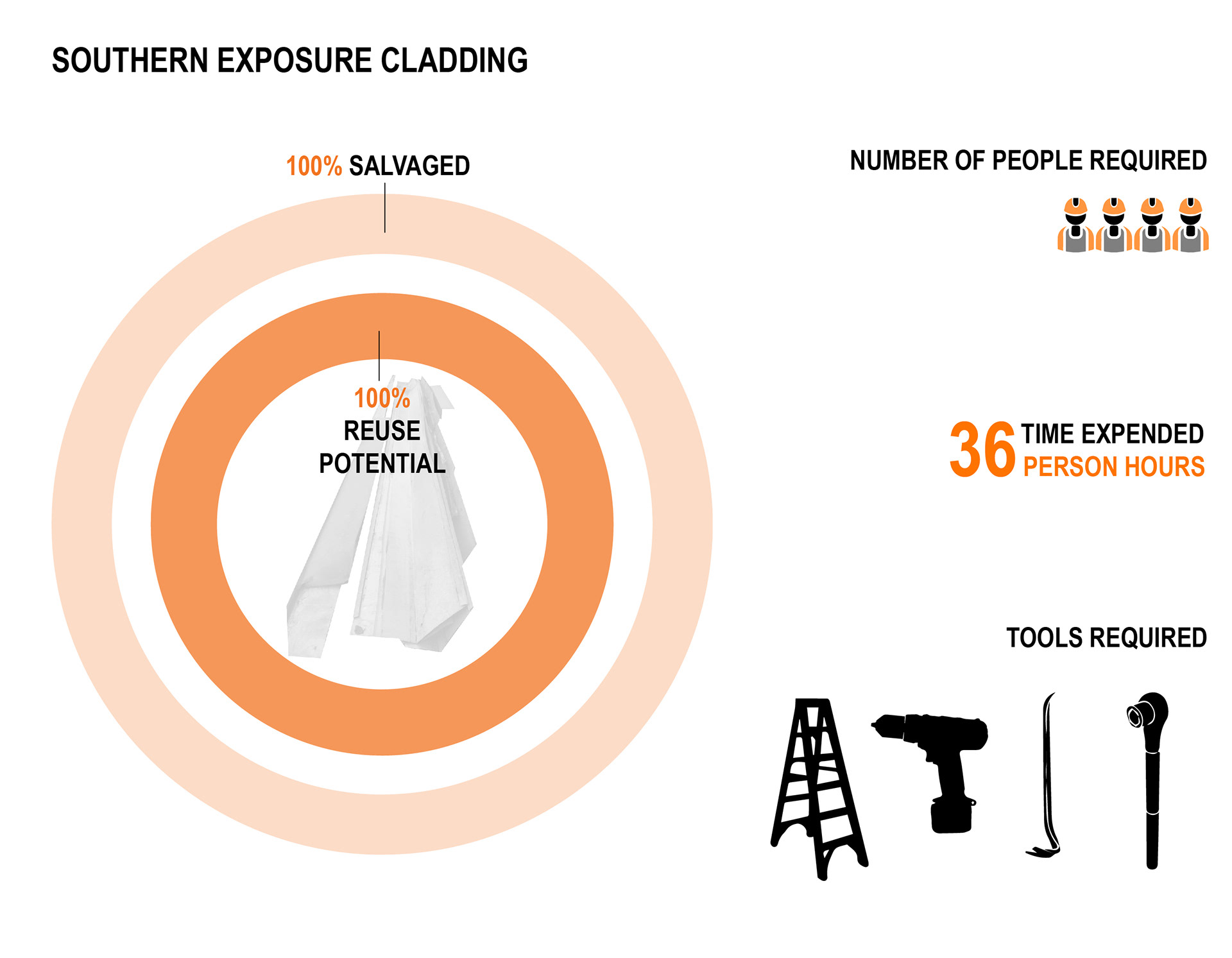

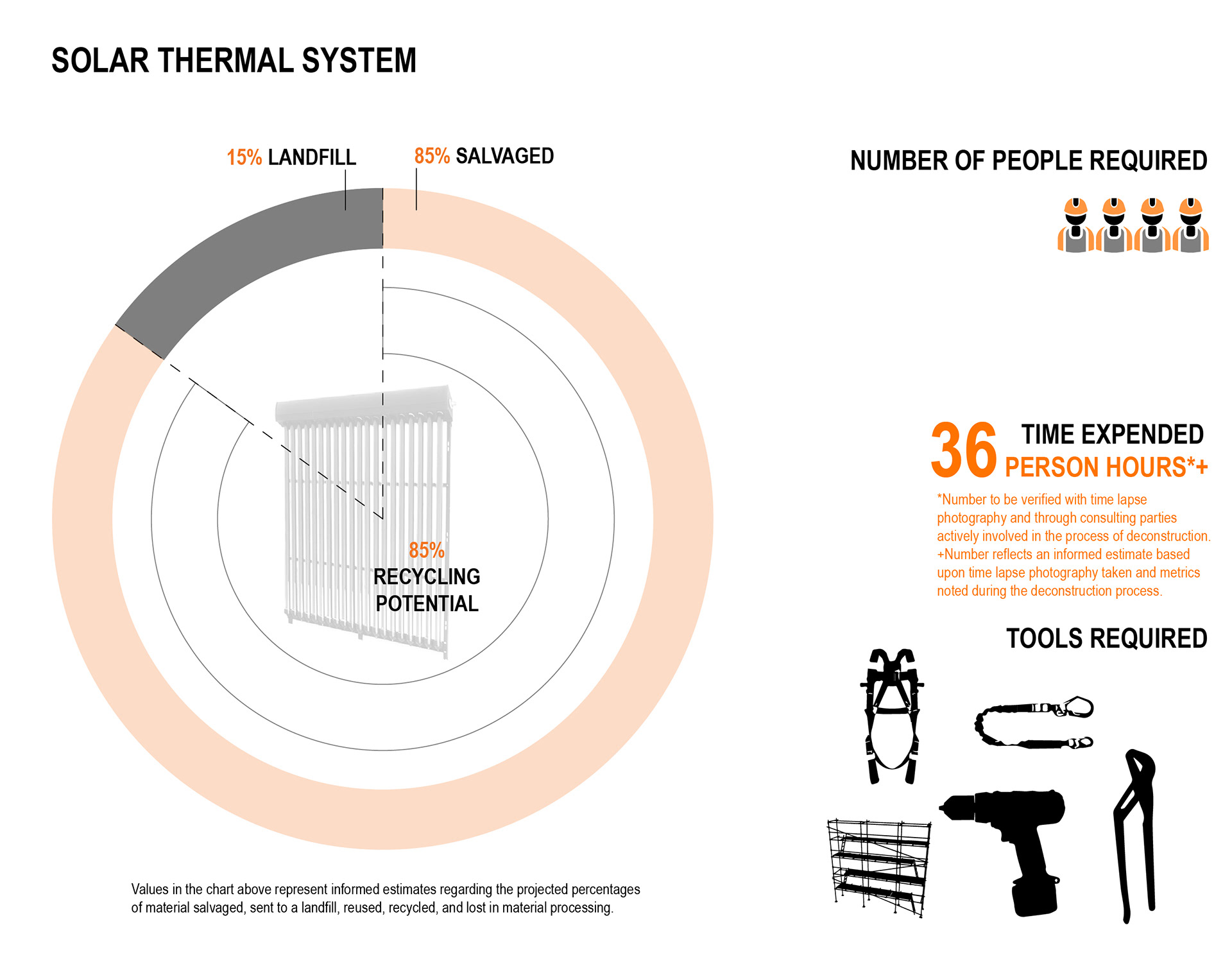

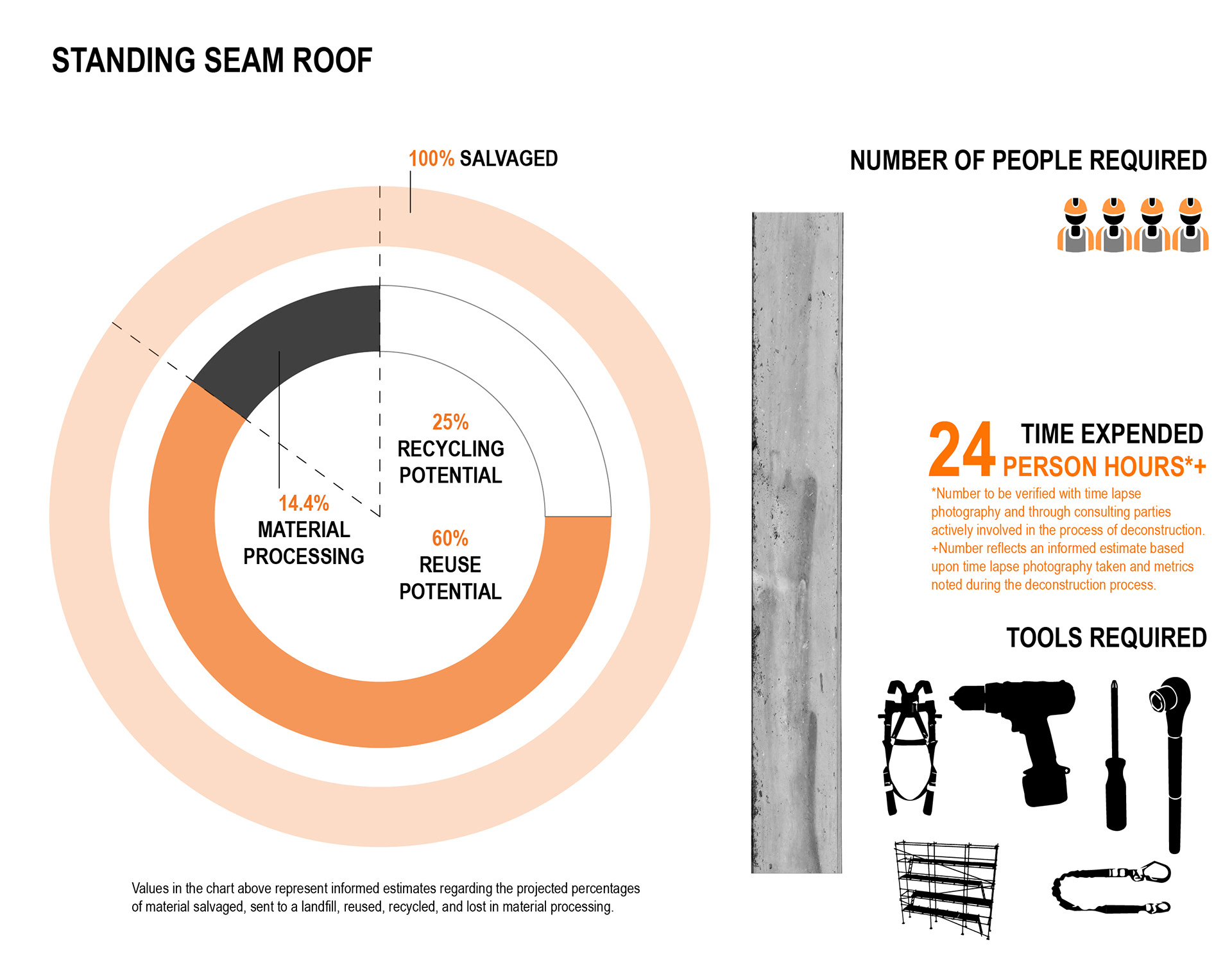

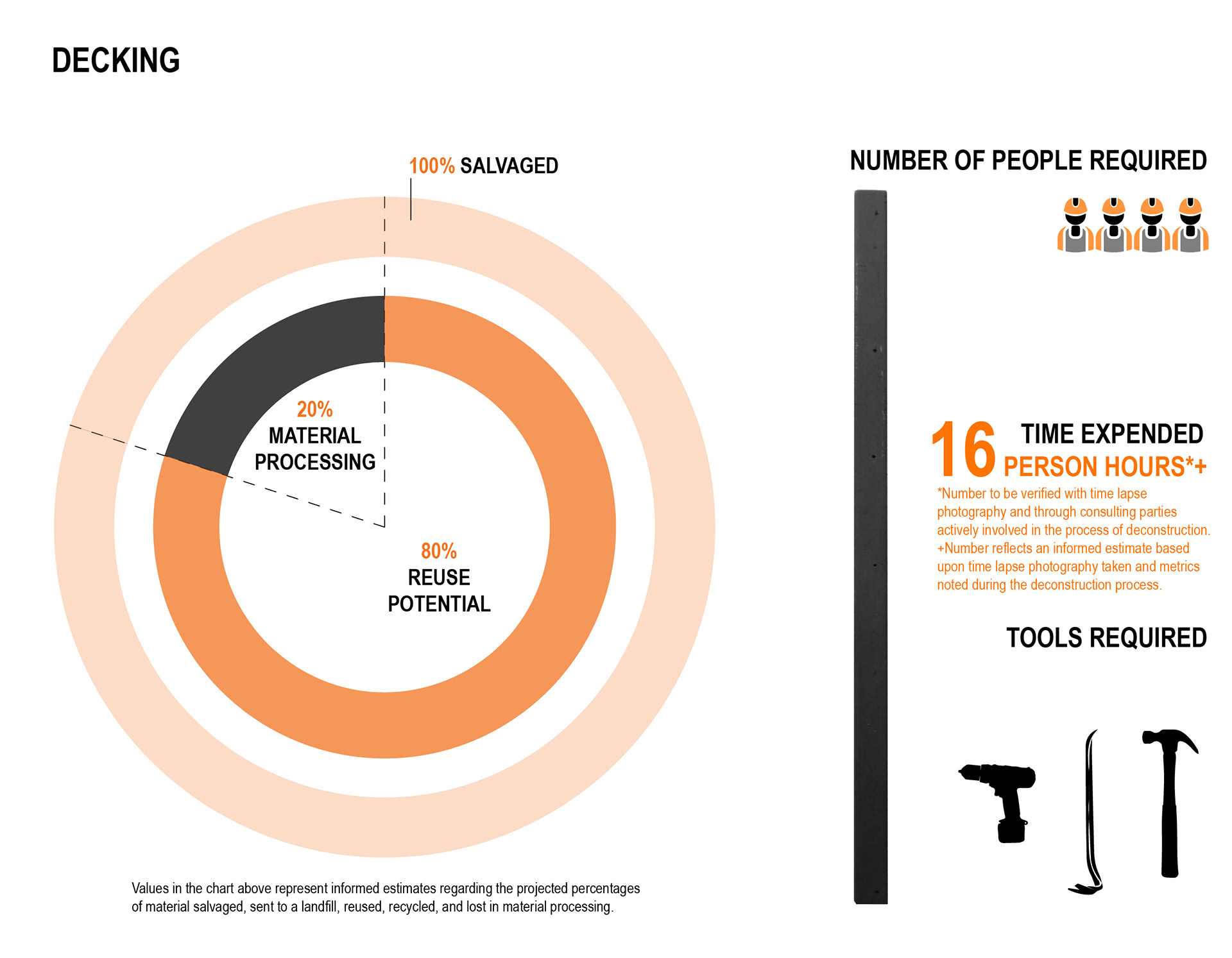

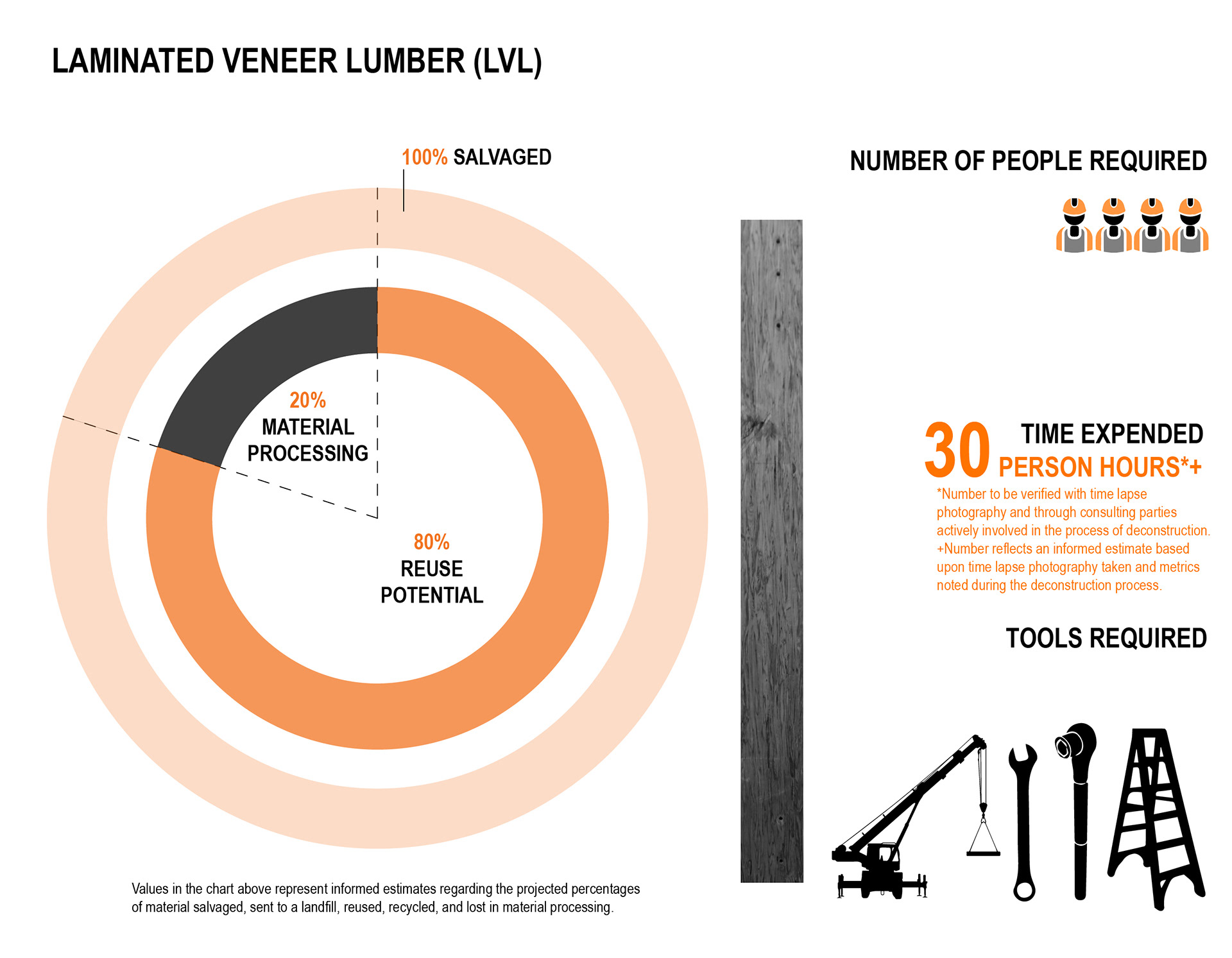

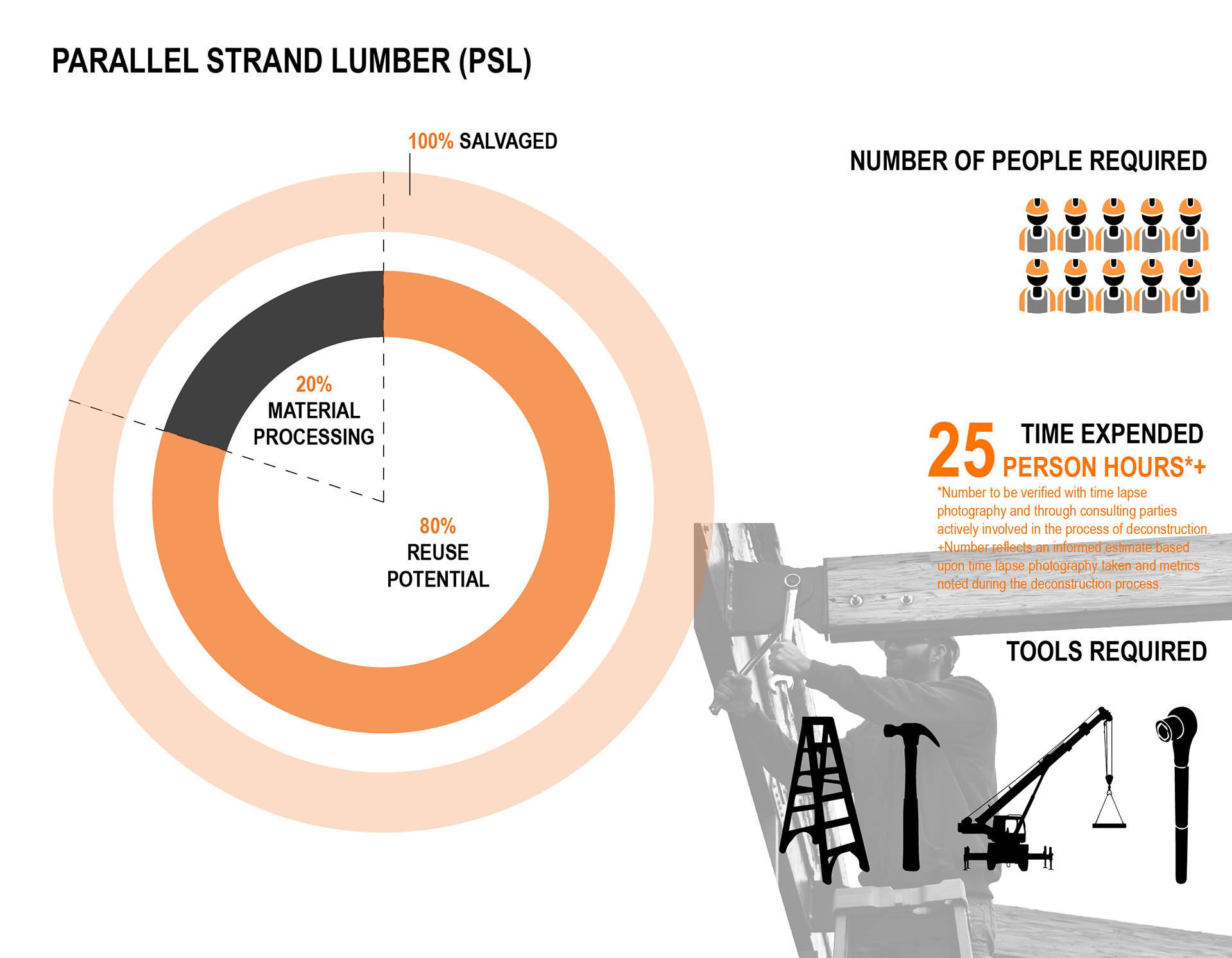

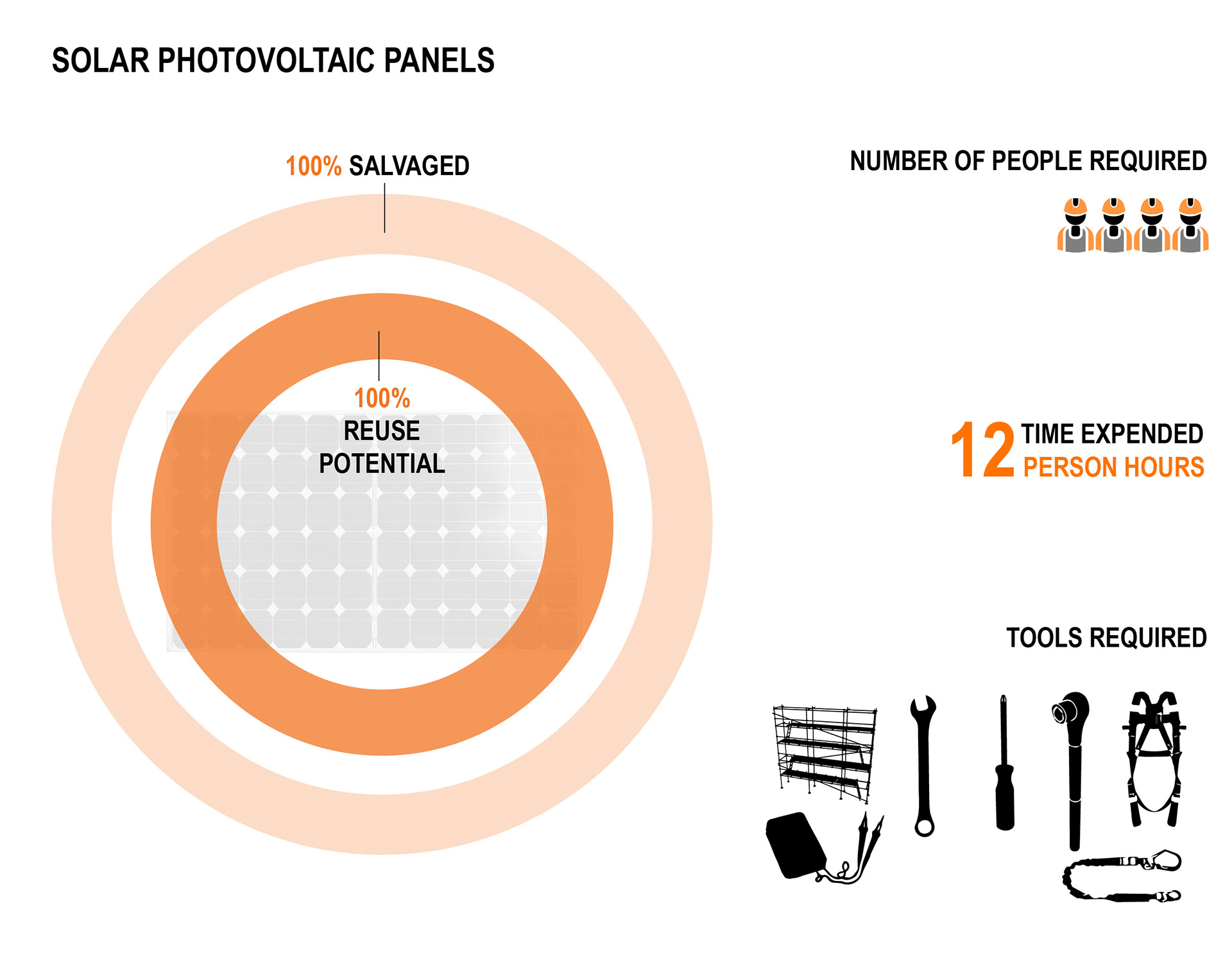

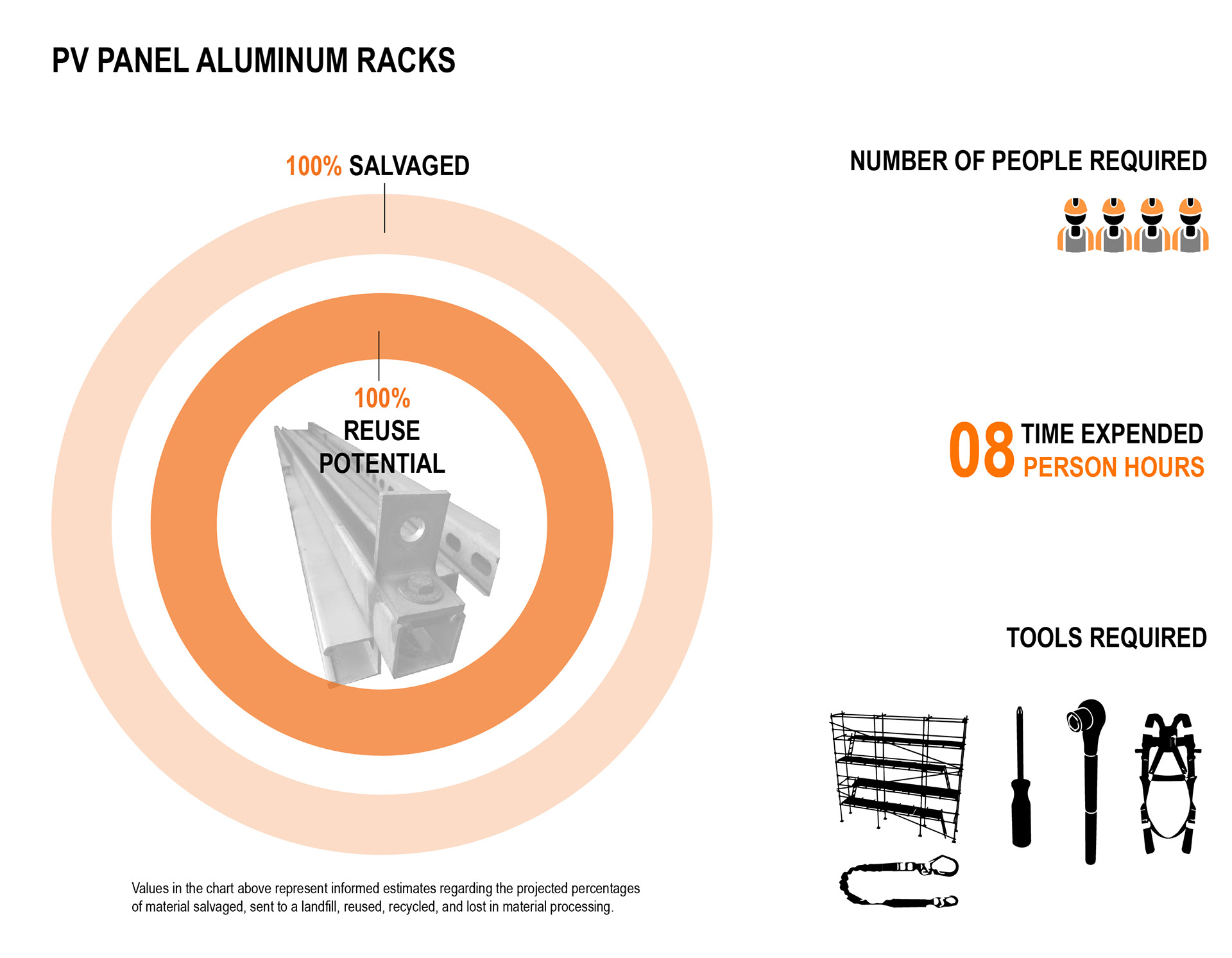

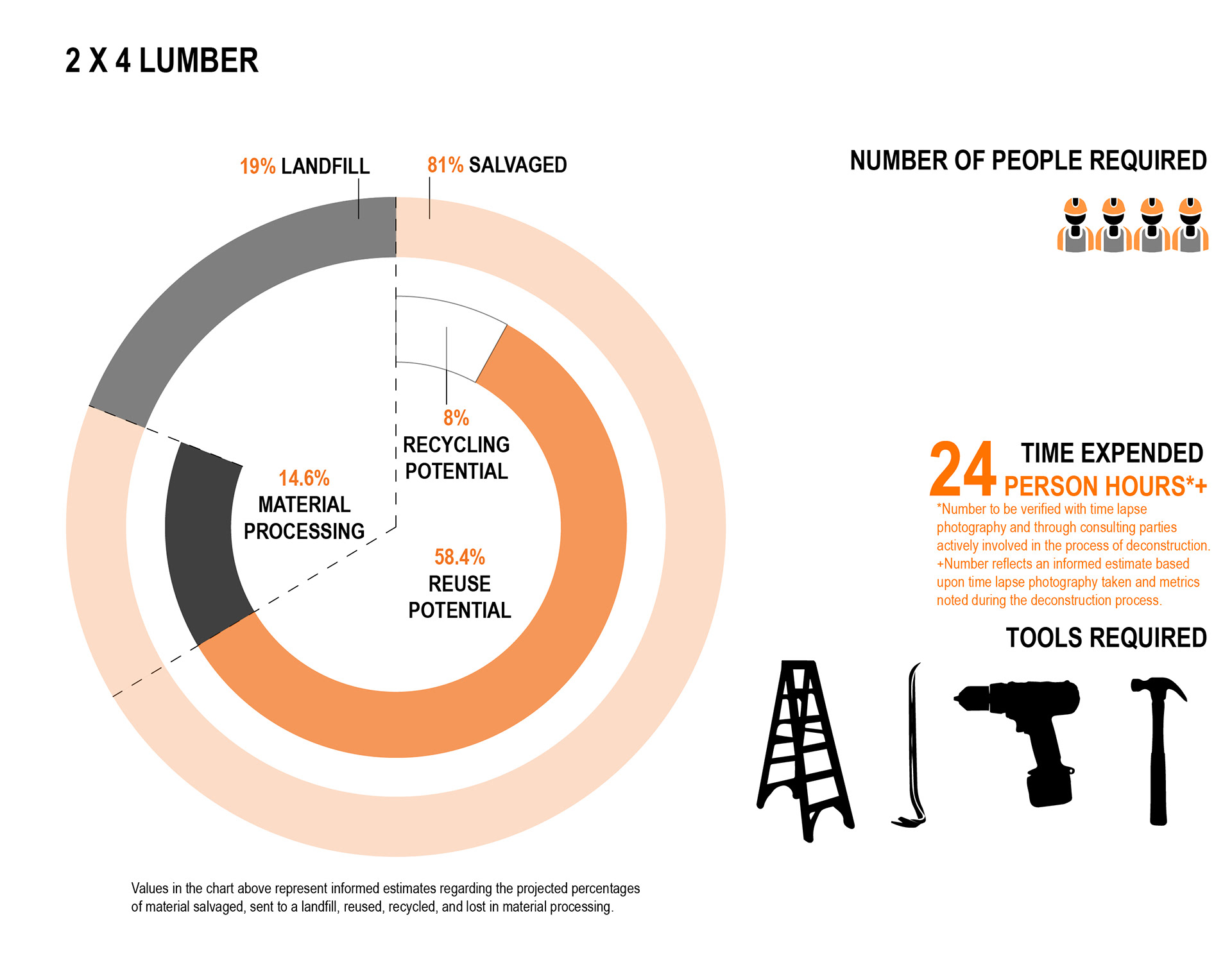

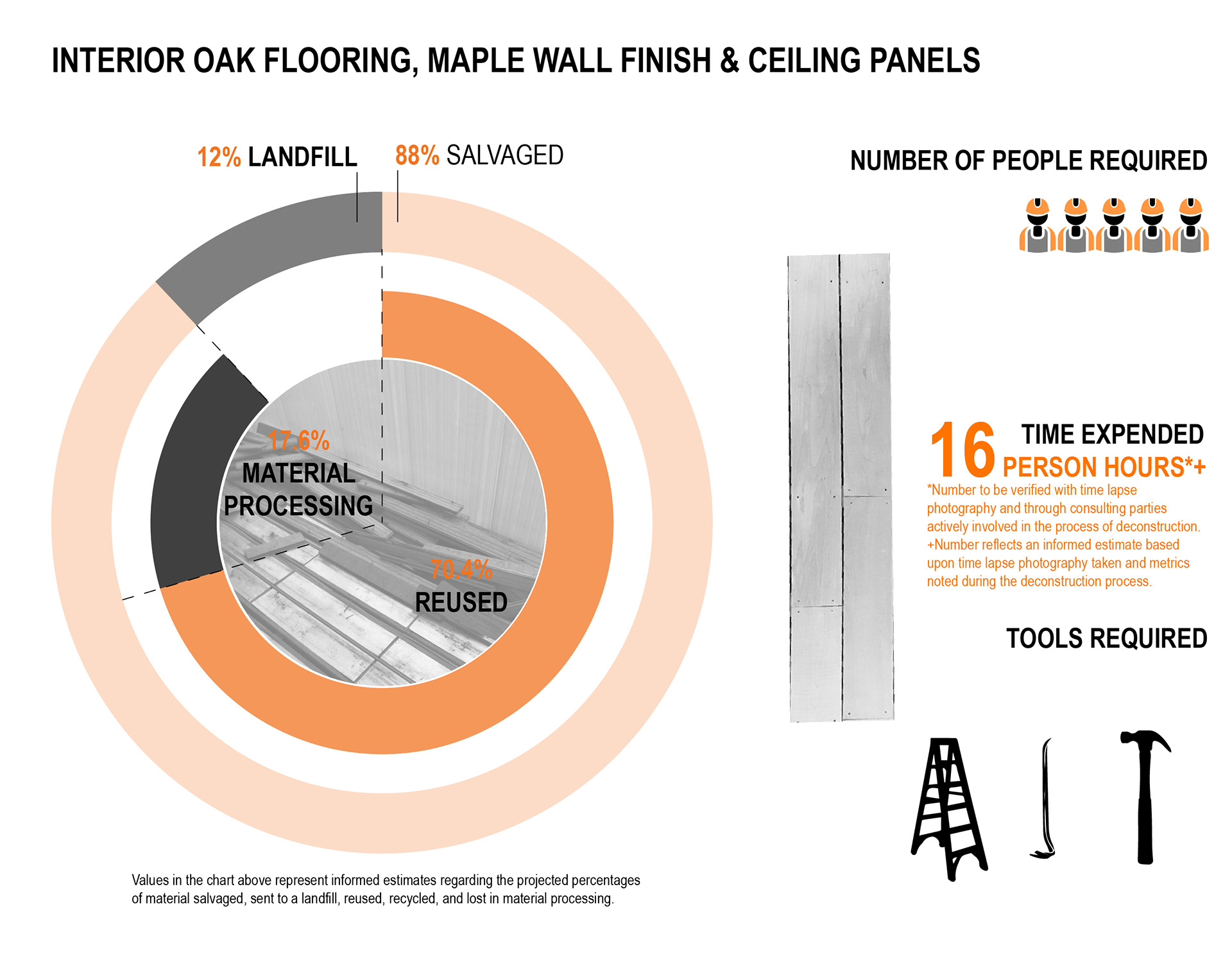

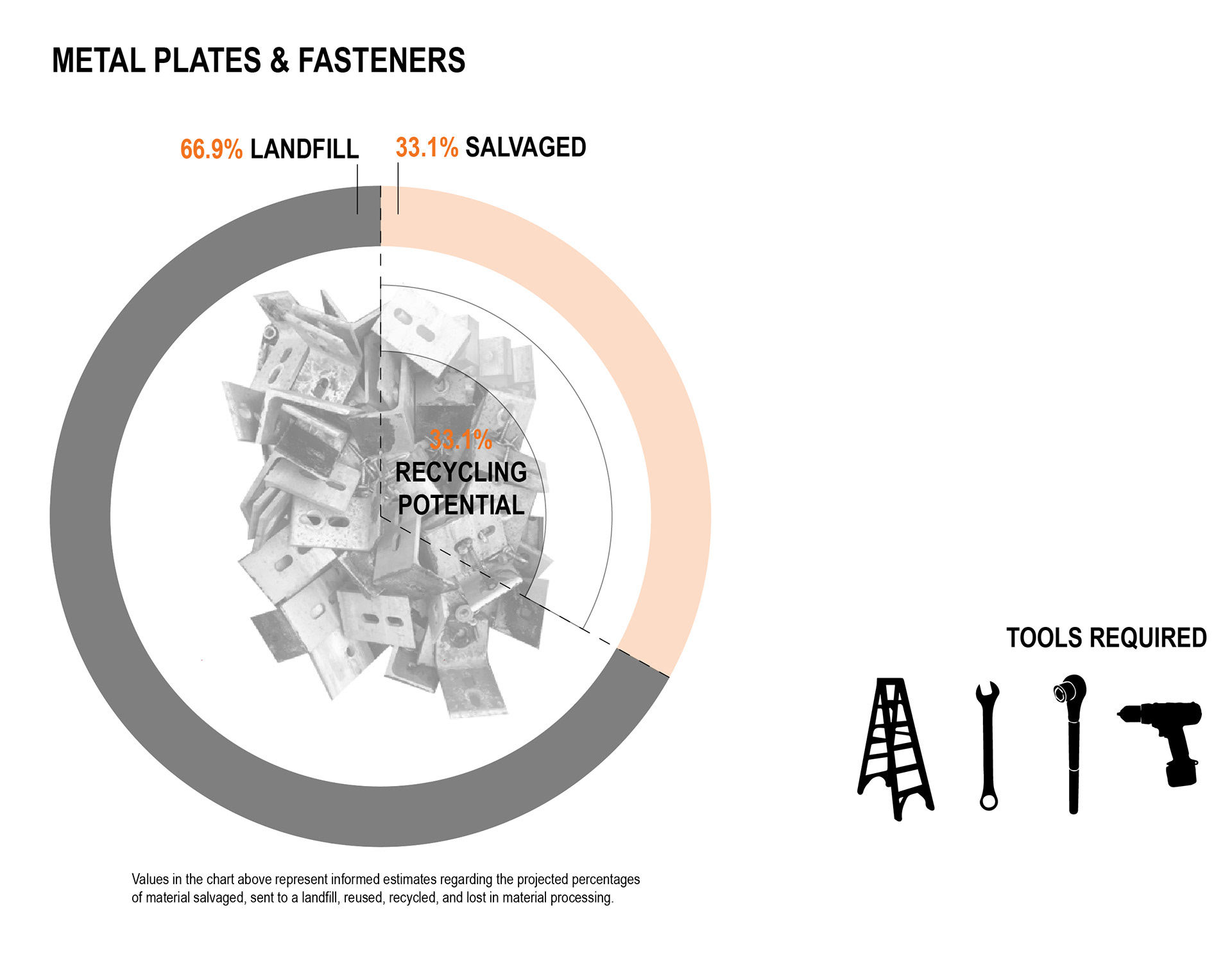

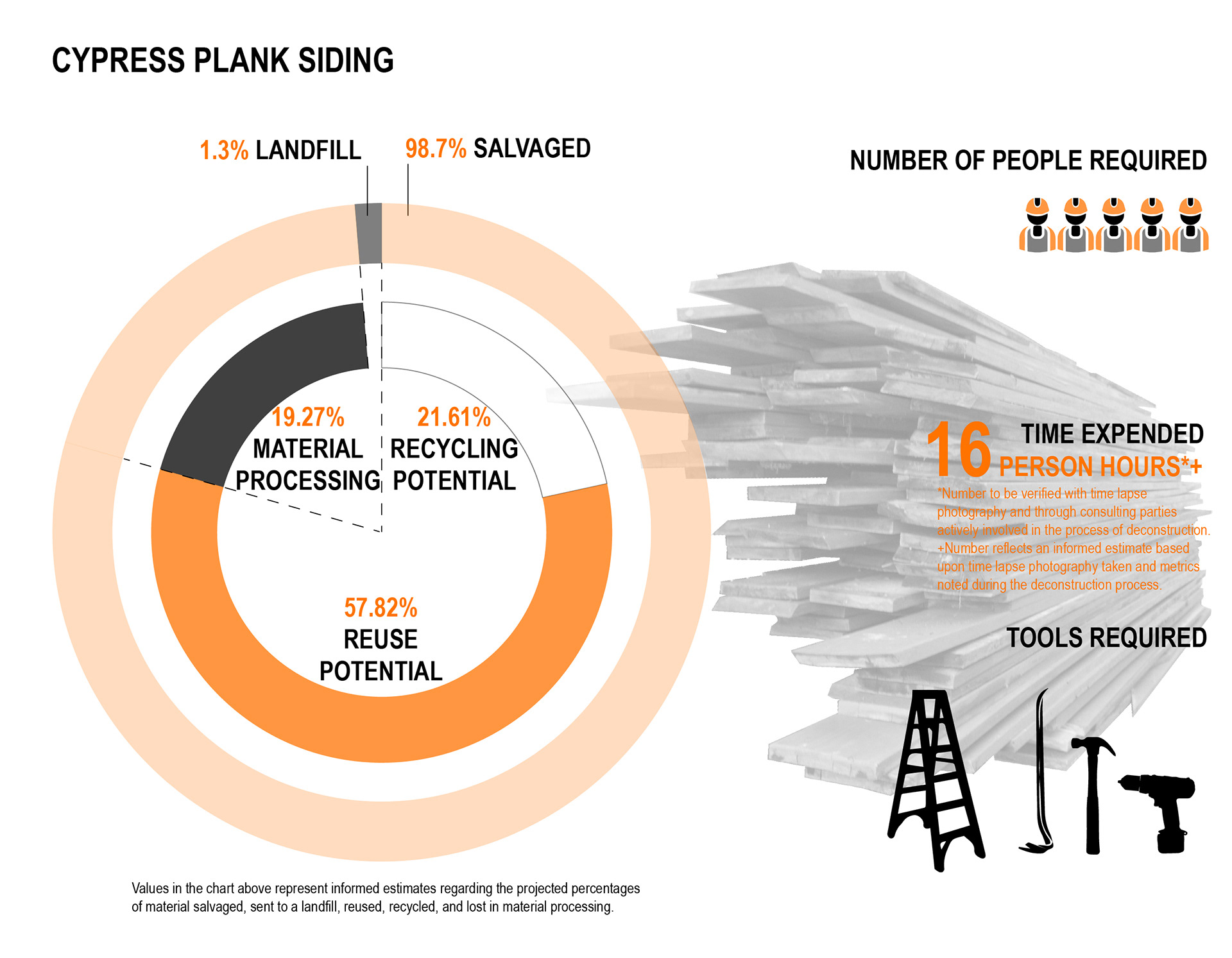

Deconstruction Material Reuse Breakdown Diagrams

After undergoing the process of deconstruction, the material that has been diverted from the landfill and has been determined to be able to be of use must be sorted, separated, wrapped, and sent to its respective destinations. In order to better understand the variety of destinations where material is projected to end up, I developed a graphic to represent these possibilities. In the example of Cypress Plank Siding, it is possible to see how the deconstructed material continues its life. On the right are educated estimates of the number of people, the estimated quantity of person-hours, and the tools required to deconstruct the material based on written records, time-lapse footage, still photography, film, and the individual records of participants. On the left, is a two-layered pie chart which describes the initial yield on the outer layer which is broken down in the inner layer. In this case, the calculations performed based on data collected by the Architecture-Engineering-Construction Management (AECM) students estimated that 98.7% of the planks would be salvaged with 1.3% of the planks being sent to landfill whether due to damage in deconstructing, damage to the material in the current use, or other reasons that reduce the materials’ usefulness. Of the 98.7% salvaged, 21.61% were calculated to have recycling potential as perhaps wood chips, mulch, or other wood products. The other 77.09% was determined to be more fitting to be reused. However, this percentage of the material will inevitably generate some waste sent to either landfill or recycled in material manipulation processes, thus of the reused material, it is broken down into an estimate of 19.27% being lost in processing with 57.82% of the material becoming a reusable product.

This breakdown graphic has been applied to many other materials that were deconstructed during DE_CON 01 as a representation of the life of the materials after being deconstructed. It will also serve as a foundation for future deconstruction projects to get an idea of the ultimate yield of the potential projects.

Deconstruction Tool Portfolio

Deconstruction provides much opportunity outside of its environmental and health benefits, specifically in the realm of job creation and creating demand for a skilled labor force. By nature of having to compete with demolition (in cases where deconstruction is not mandated) and requiring careful attention to budget and labor costs, deconstruction must function with a strict margin of finances. Despite this, it outperforms demolition in “[creating] 6 to 8 jobs [for every one that demolition creates]” (Details). As part of the studio’s assessment of the Deconstruction of the Solar Decathlon House, the Architecture-Engineering-Construction Management cohort took note of the tools required in deconstructing specific materials. This information was then represented to serve as a reference portfolio for deconstruction trainees to use in seeking out jobs after their training. Furthermore, the tool portfolio shows the range of equipment needed to deconstruct even a small, modular structure, albeit one that was fully conditioned and serviced in regards to mechanical systems.

Given that the deconstruction of the Solar Decathlon House was done by a numerically over-sized team and on a short timeline, one of the key inefficiencies was tool management. With so many people working at the same time, on different parts of the building, and interacting with a variety of systems, finding the right tool with a correctly sized attachment and diligently checking tools out caused large time inefficiencies. Furthermore, as there were many teams simultaneously working on different materials and systems, there was sometimes a lack of available tools to complete tasks in a more efficient way. These issues, however, are inherently tied to compressing the timeline of the deconstruction project and involving so many people to deconstruct. In general, deconstruction projects are more commonly completed by a smaller group focusing on one specific system at a time which eliminates some of the issues we experienced.

Sources

Details. “Why Deconstruct?” Details, Details, www.details.org/whydeconstruct/.

Expediting Reuse Graphics

In order to better facilitate future use of the graphic previously mentioned, I prepared a Grasshopper script for future use which takes three inputs and reduces the hassle of making the diagrams. The script takes inputs of the percentages of material salvaged, recycled, and lost to material processing and creates a framework of lines for the diagram. It calculates simple geometry rotations to formulate the structure of a layered pie chart, relieving the diagram-maker of having to run calculations for how many degrees/radians to rotate or where to trim lines. This basic geometry can then be exported from Rhinoceros into Illustrator to post process and then be formatted alongside the other deconstruction information. This script dramatically reduces the amount of work that needs to be done and increases the efficiency of generating these diagrams. It was helpful during the analysis of DE_CON 01 and could serve as a resource for future projects as a way of disseminating information about the physical and material impact/yield of deconstruction projects.

Material Sorting & Processing

In regards to quantifying what material could be re-purposed in RE_CON, a cohort of students from the UDBS worked with Professor Folan and Fellow Rauck in Project Re_ at Construction Junction to begin sorting through and quantifying the materials that had been deconstructed, transported, and stored there during DE_CON 01. Tasks varied throughout the day and an effort was made to begin imagining ways in which the materials could be reused in RE_CON. In order to catalog all of the materials there, students were broken up into groups which were assigned to pallets to sort. Materials were sorted for what was useful, denailed to allow for stacking, cataloged, wrapped, then organized by material type into large boxes for storage. In order to begin understanding the quantity of material and its possible uses, it was crucial to go through the material and begin understanding not only what materials could be re-purposed as and where they could find a home in RE_CON, but also to comprehend the amount of labor that re-purposing materials implies and how material can be lost based on its condition and how it was used previous to deconstruction. From wooden members that were part of joinery systems or had been efficiently laminated, to unequal lengths of members and fractured pieces, these imperfections ultimately have a significant impact on the useful yield of the deconstruction and have been cataloged taking these factors into account so as to not overestimate the quantity of material that can be applied and designed with. This process will serve to not only better understand what the process of deconstruction entails with more accurate data of how the material breakdowns turned out, but also to connect the process to the RE_CON housing prototype.

DE_CON Game

Working in collaboration with the Reality Computing students at CMU’s IDeATe Department, one of the final projects for the Reality Computing students was a deconstruction game catered to job skills training. Given models and information regarding building deconstruction processes relayed from the UDBS, the team of Reality Computing students created a strong foundation of work representing a variety of critical of interactions, from teleporting around the space and picking up objects, to using tools to deconstruct a solar panel array and designing an interaction feedback loop for knowing when screws were fully unscrewed. While still in development, this game could be further updated to represent more material systems and eventually cover the most common materials that deconstructors would encounter on jobs, supplementing the experience with concepts and information of material breakdowns. By creating a platform of conveying information and getting simulated practice with deconstructing, this game could eventually become a powerful tool for teaching deconstruction principles and processes in a safer, more manageable, and more entertaining manner to deconstruction trainees. Furthermore, with the amount of time the students were allotted and their ambitious goals, they have made great strides and have developed a strong jumping off point. My role in this process was acting as the liaison between the Reality Computing students and the UDBS cohort. Although difficult with the various scheduling conflicts and the gap in software experience gap in regards to Unity, I find virtual reality experiences quite intriguing and do hope to become more involved in this sort of work and delve deeper into how these new technologies can be implemented to advocate for and compel change.

For more information about the project, studio, and context in a publication format, feel free to read through the book below!

Urban Design Build Studio

I participated in this project as part of a larger collaborative cohort, for more information, follow this link to learn more about the team and the context of the studio!